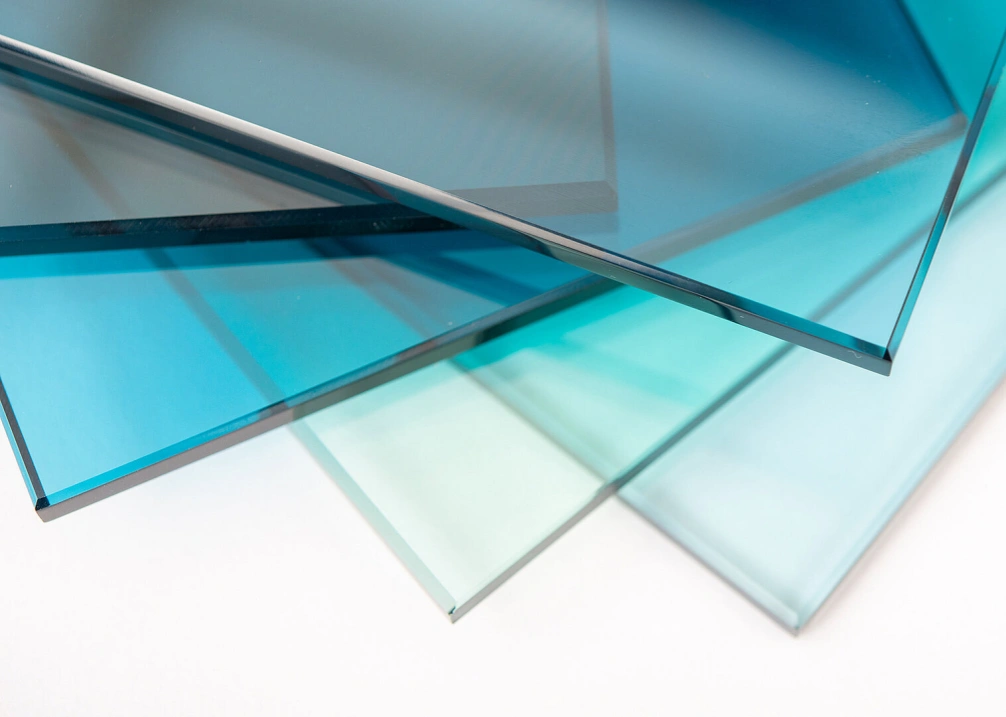

Tempered glass, also known as toughened glass or reinforced glass, is a type of safety glass that has been processed by controlled thermal or chemical treatments to increase its strength compared with normal glass.

Certifications

ISO9001:2015 | ANSIZ97.1-2015 | AS/NZS2008:1996 | EN14449:2015+AC:2005

At GLASVUE, we specialize in the production and processing of high-quality tempered glass. Our advanced techniques and stringent quality control measures ensure that we meet the diverse needs of our clients. Here are some of the key tempered glass processing services we offer:

With our state-of-the-art equipment and a team of highly experienced professionals, we guarantee the production of tempered glass that meets 100% of your requirements

Glass is heated to a softened state at a high temperature (around 650°C) and then rapidly cooled.

This process creates a uniform and strong compressive stress on the surface of the glass, while the interior forms a uniform and strong tensile stress. As a result, the mechanical strength and thermal stability of the glass are significantly enhanced.

This type of glass is known as tempered glass.

The impact resistance of tempered glass is 3-5 times that of ordinary glass.

The bending strength of tempered glass is 4-5 times that of ordinary flat glass.

When broken, tempered glass forms blunt particles that are less likely to cause injury, providing a high level of safety.

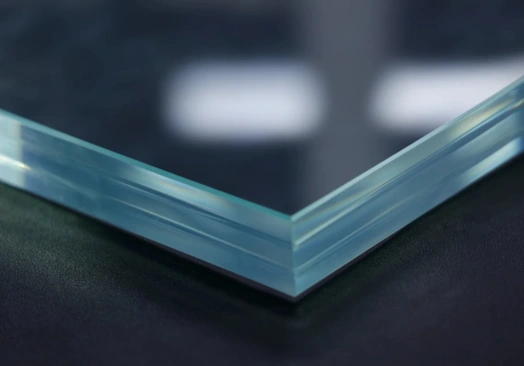

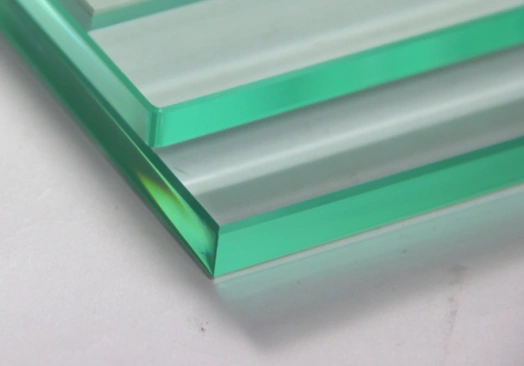

The edges of the glass are treated according to different thicknesses and specifications. The main purpose is to eliminate micro-cracks on the edges to prevent breakage during heating and to improve the yield. (Due to the differences in thickness and specifications, the time required to reach the softening temperature varies. Glass with longer heating times requires higher edge treatment standards.)

Specialized equipment is used to clean the surface of the glass, removing stains and impurities, and drying the glass to ensure surface quality.

The glass is uniformly heated to a softening temperature of 650°C. Due to differences in the glass surface and thickness, the heating time will vary. Longer heating times can cause stress spots and pinholes on the glass surface, leading to quality issues.

The high-temperature glass is rapidly cooled with cold air, causing significant changes in its internal molecular structure. This process creates a uniform and strong compressive stress on the surface and a uniform and strong tensile stress internally, significantly increasing the mechanical strength of the glass, thus forming tempered glass.

The tempered glass is sealed in specialized equipment for high-temperature and high-pressure treatment to trigger the breakage of glass with uneven internal stress and potential spontaneous breakage risks.

The surface of the tempered glass product needs to be cleaned and dried before packaging.

For over 30 years, GLASVUE has set the benchmark in the architectural glass industry by continuously optimizing our equipment and production processes. Our commitment to high standards ensures that we deliver tempered glass that meets 100% of your requirements efficiently.

Depends on your tempered glass customization. All glass types and production processing will affect its costs. You can send us your tempered glass drawings to get an accurate quote.

In addition, the wholesale quantity and logistics costs from China can add to all the cost. You can ask our specialists for help.

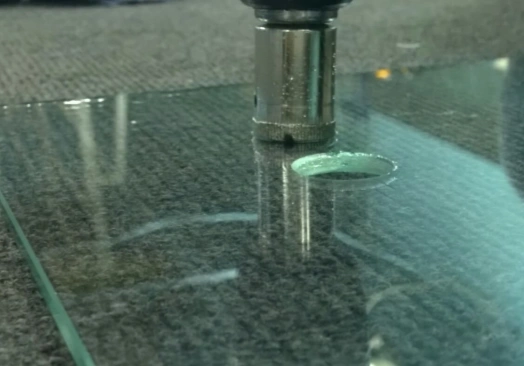

Absolutely. We have an independant technical department for CNC glass machining for precise glass manufacturing. You can rest assured for the installation of your glass.

Experience the quality of GLASVUE glass firsthand with a complimentary sample tailored to your project requirements.

Let us design a glass solution that perfectly aligns with your unique architectural vision and technical specifications.

Access detailed technical data sheets for GLASVUE’s architectural glass products, including performance metrics and installation guidelines.

Gain inspiration from our curated collection of successful GLASVUE installations worldwide, showcasing innovative applications of architectural glass.