Safety glass is a strong material made to keep people safe. It breaks into tiny, safe pieces or holds cracks together. You’ll find it in buildings, cars, and public places. It’s tough and protects well. Brands like GLASVUE make great safety glass solutions, mixing safety with nice looks. Choosing the right kind depends on what you need—like stopping impacts, blocking fire, or cutting noise—making safety glass super important for today’s buildings and risky spots.

What is Safety Glass and Why is it Essential?

Defining Safety Glass

Safety glass is built to protect when it breaks. Regular glass splits into sharp, harmful pieces. Safety glass, though, either crumbles into small, safe bits or stays together. This makes it perfect for places where staying safe matters a lot.

Why is Safety Glass Becoming Increasingly Important?

More and more people use safety glass in different areas. These include construction, car-making, and furniture. It’s strong against hits and keeps people safe if it breaks. Plus, it blocks sound, traps heat, and can look pretty. It comes in cool styles, like colored or patterned glass. Some types even clean themselves or dim with smart tech.

What Are the Core Features of Safety Glass?

Definition of Safety Glass

Safety glass is any glass made or treated to lower injury risks when it breaks. Special steps make it tougher and change how it splits, keeping everyone safer.

Two Core Properties of Safety Glass

Impact Resistance

Safety glass is really strong. It can handle big hits without breaking fast. This stops break-ins or accidents from happening.

Post-Breakage Injury Prevention

When safety glass breaks, it doesn’t make sharp bits. Tempered glass turns into small, dull pieces. Laminated glass keeps broken parts stuck in its middle layer, so they don’t fly around.

What Are the Key Types of Safety Glass?

The key types of safety glass include tempered, laminated, wired, and fire-resistant glass.

Tempered Safety Glass

Principle of Tempered Glass

Tempered glass is made by heating glass super hot, then cooling it fast. This makes it way stronger than normal glass.

Characteristics of Tempered Glass

This glass is tough, handles heat great, and breaks into tiny, safe bits instead of sharp chunks. It’s a solid pick for staying safe.

Applications of Tempered Glass

You’ll spot tempered glass in cars, home decorations, and big building windows. Its strength and safe breaking make it awesome for these jobs.

Laminated Safety Glass

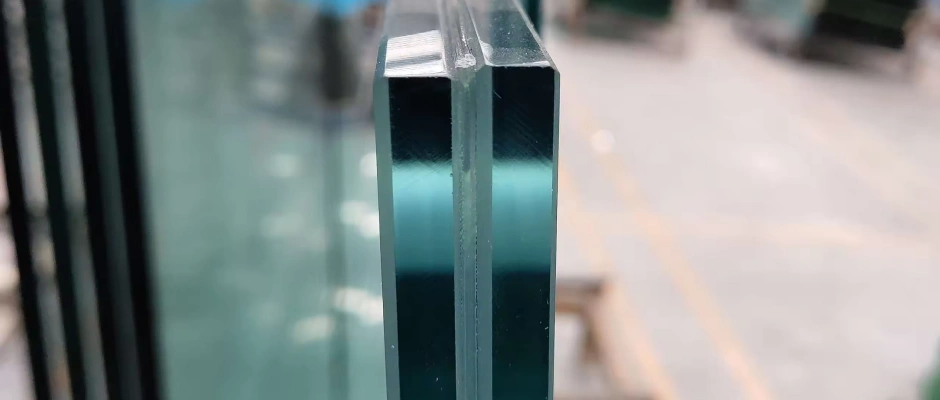

Structure and Composition of Laminated Glass

Laminated glass is made by gluing two or more glass layers with a middle layer. This part is usually PVB (polyvinyl butyral), EVA (ethylene-vinyl acetate), or SGP (SentryGlas Plus).

GLASVUE Laminated Glass Solutions

Look at GLASVUE’s safety glass solutions for cool building ideas. Their laminated glass is strong, cuts noise, and blocks UV rays. It’s a smart choice for safety.

Different Interlayer Functions of Laminated Glass

The middle layer in laminated glass does more stuff. It quiets down noise, like low or medium sounds. It also stops over 99% of UV rays, keeping places safer and better for you.

Wired Safety Glass

Principle of Wired Safety Glass

While the glass is still in a softened state at high temperatures (around 900°C), a preheated metal wire mesh is pressed directly into the middle of the glass. As the glass cools and solidifies, it forms a single monolithic sheet with the wire mesh embedded inside.

Characteristics of Wired Safety Glass

Safety

When broken, the glass fragments remain held together by the embedded wire mesh, preventing dangerous shattering.

Fire Resistance

The glass remains in place under short-term high temperatures, making it suitable as auxiliary fire-resistant glazing.

Security

The metal wire mesh provides additional impact resistance, making it more difficult to break through instantly.

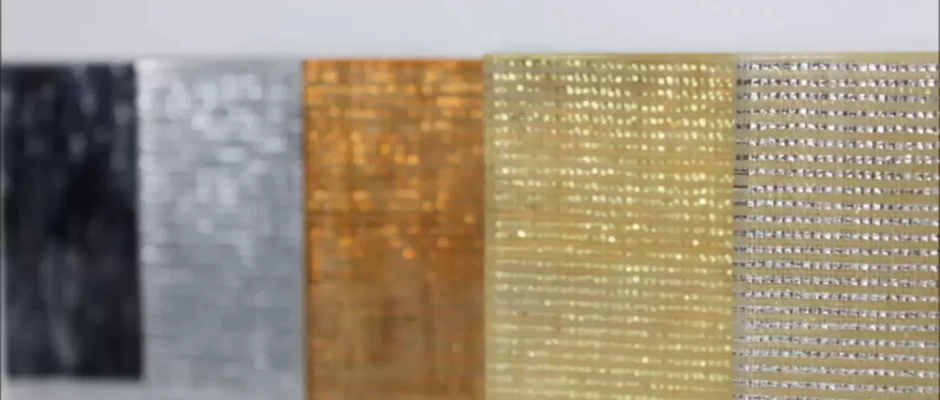

Aesthetics

Available in various wire mesh patterns to create an industrial or vintage design style.

Applications of Wired Safety Glass

Wired glass is used in fireproof doors and windows. It stops fires from spreading and stays strong against break-ins.

Fire Resistant Glass

Principle of Fire-Resistant Glass

Fire-resistant glass has special coatings or layers to deal with super-hot temperatures. It doesn’t fall apart easily in fires.

Characteristics of Fire-Resistant Glass

This glass stops fire, smoke, and heat. It’s made to stay solid in rough conditions, keeping folks safe.

Applications of Fire-Resistant Glass

You’ll see fire-resistant glass in public buildings where fire safety is a big deal. It can take high heat for a certain time, based on ratings like Class A (full heat block), Class B (some heat block), or Class C (no heat block).

Explanation of Fire Resistance Ratings

Fire ratings tell how long glass can stay strong in a fire. This gives people time to get out safely during a fire.

Technical Principles of Safety Performance

How Does Stress Distribution and Fracture Mode Enhance Safety?

Tempered glass relies on balanced surface compressive stress and internal tensile stress for its safety performance. Proper stress distribution improves impact resistance, thermal stability, and safe breakage. Uneven, excessive, or insufficient stress can lead to breakage, spontaneous shattering, deformation, or certification failures. When tempered glass breaks, it forms small, blunt granules. Laminated glass retains fragments within its interlayer, further reducing injury risks.

When tempered glass breaks, it forms small, blunt bits, not sharp ones. This lowers the chance of getting hurt. Laminated glass keeps broken pieces in its middle layer, adding more safety.

Why is Interlayer Bonding Crucial for Energy Absorption?

The middle layer in laminated glass is super important. Stuff like PVB or SGP sticks tight to the glass. It soaks up the hit energy, stopping the glass from breaking through. Making rooms quieter and safer.

What Mechanisms Ensure Fire and Explosion Resistance?

Fire-resistant glass uses special coatings or layers to handle high heat. Class A glass blocks all heat. Class B and C block some heat or just stop the fire. These features make it key for public places needing strong fire safety.

Standards and Certification Systems

Chinese GB standards set tough rules for safety glass. They check how strong it is and how it acts when broken. These rules make sure the glass is safe for buildings and cars.

Australian/New Zealand Standard (AS/NZS 2208:1996): Certifies safety glass for use in architectural applications like curtain walls and windows in Australia and New Zealand.

American Standard (ANSI Z97.1 – 2015): Covers strength, heat resistance, and impact resistance for safety glass in the U.S.

Selection Recommendations for Different Applications

| Application Area | Recommended Glass Structure | Description |

| Residential Doors/Windows | Tempered Insulated Glass, Laminated Insulated | Basic safety + energy-efficient insulation |

| Curtain Wall Systems | Tempered Laminated Glass, Insulated Laminated | Wind pressure resistance + fall prevention |

| Balcony Railings | Tempered Laminated Glass | Fall prevention + impact resistance |

| Skylights/Roof Glazing | Laminated Tempered + Insulated | Heat insulation + explosion/fall prevention |

| Commercial Stores/Corridors | Tempered Glass, Wired Glass | Safety + aesthetic appeal |

| Fire-Prone Areas | Fire-Resistant Laminated Glass, Wired Glass | Flame-retardant partitioning |

Glasvue – A Trusted Architectural Glass Manufacturer

Why Choose Glasvue’s Expertise?

With 29 years and over 17,600 buildings helped worldwide, GLASVUE is a top name in safety glass solutions. Their laminated glass mixes strength and style, great for modern buildings. Check out GLASVUE’s safety glass solutions for new, trusty products.

How Does In-House Production Benefit You?

GLASVUE’s modern factories make every product with care. They watch quality at every step, giving glass that hits high standards.

What Sets Glasvue Apart in Compliance?

All GLASVUE products meet world standards like GB (China), EN (Europe), AS/NZS(Australia/New Zealand) and ANSI/IGMA (U.S.). This makes their glass fit for projects everywhere.

FAQ

Q1: Is tempered glass safe even when broken?

A: Not totally. Its bits are less sharp, but falling glass can still cause harm.

Q2: Is laminated glass always safer than tempered glass?

A: Depends on the job. Laminated glass stops bits from flying, but tempered glass is tougher at first.

Q3: What is the relationship between tempered glass and laminated glass?

A: Tempered glass can be used as a base layer for laminated glass. For enhanced impact resistance, tempered glass can be laminated with an interlayer.