As design paradigms evolve in 2025, Biophilic Design and Minimalism have emerged as the defining hallmarks of high-end architectural typologies. Think about those smooth curtain walls on big city towers or the tall windows stretching from floor to ceiling in beach houses. The demands for sharp vision have climbed to levels never seen before. Builders these days push hard for a kind of outer shell that feels almost unseen. It pulls in the cleanest sunlight from nature and gives real, true sights of the world outside. This approach lets people inside connect deeply with their surroundings in a natural way.

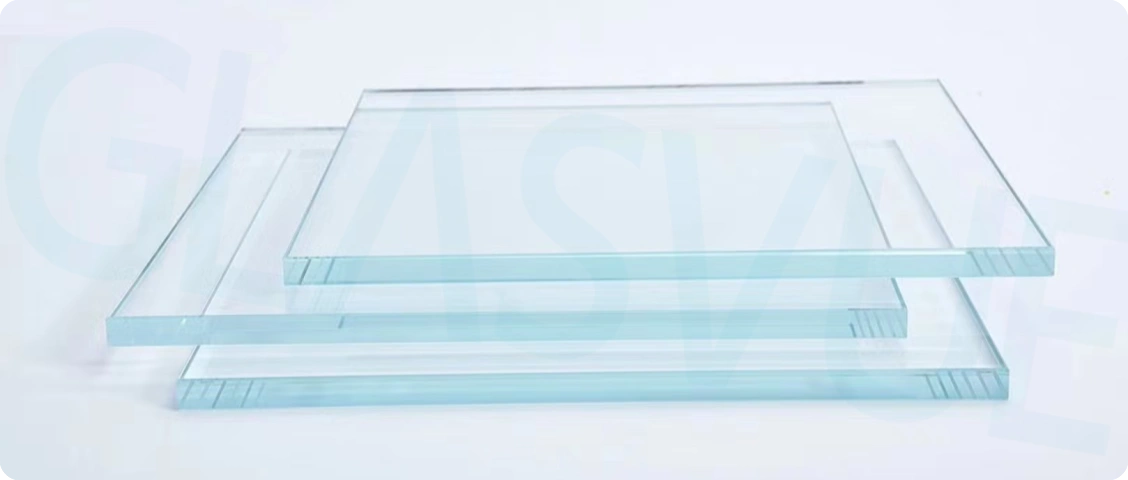

But this dream hits a real roadblock from basic science rules. Standard float glass possesses an inherent green tint, primarily attributed to the residual iron oxide content within the raw materials. In just one slim piece, it might not stand out much. However, when you stack several layers for insulation or build thick glued setups like in current projects, that tint gets way stronger. It turns into a foggy barrier. This messes up how colors look and weakens the clear style that designers spend so much effort building.

The strong push for the best possible sharpness led to the creation of Glasvue. It pairs up Low-Iron Glass with smart Heat Strengthening techniques. Glasvue wipes out any sight distractions. It helps builders and window companies across the globe get past the limits of everyday materials. In the end, they can make the dream of “Absolute Transparency” come true in real buildings.

Deconstructing “Absolute Transparency”

If you want to see why low-iron glass now acts as the top pick for today’s big name buildings, start by checking the small-scale chemistry involved. The greenish color in usual flat glass comes from around 0.1% Fe₂O₃ (iron oxide) found in the sand made of silica. Those iron particles work as heavy blockers for the red tones in the light that our eyes can catch. This leads to less light getting through and big changes in color appearance.

Glasvue picks sand that has gone through tough checks and holds very clean silica to hold iron oxide down below 100 ppm (<0.01%). That’s only one-tenth of the amount in normal glass. Such a material cleanup sparks a real step up in how light passes through and looks.

Unmatched Optical Clarity (More Than 91% Visible Light Transmission): Glasvue keeps a pure, clear quality even in heavy glued setups. It does away with the shadowy “bottle green” look that shows up when normal glass stacks together. Designs that focus on natural light gain from this. They get a better Color Rendering Index (CRI). As a result, things like inside paintings, store items, and outside views show up in their actual shades without any twist.

Gem-Style Edge Shade: When edges stay open to view, such as in railings made of glass, steps, or walls without frames, the gain really pops. Low-iron glass shifts the plain, deep green border to a shiny ice-blue tone or something close to clear and see-through. This adds a fancy, gem-like feel to the small parts of the building design.

The Efficiency Myth: Does High Clarity Mean High Energy Loss?

Lots of folks hold a wrong idea that pushing light through as much as possible hurts how well heat stays in check. Truth is, low-iron glass serves as the best base layer for strong Low-E coverings. ideal substrate for high-performance Low-E coatings. Glasvue’s setups use the low-iron piece to bring in loads of daylight from outside. At the same time, layers of double or triple-silver Low-E block out the heat rays in the infrared range with exact control.

This close teamwork lets building plans hit the marks set by LEED V4 for solid views and light from day (EQ Credit). It does this while holding a small SHGC (Solar Heat Gain Coefficient) to make energy use better (EA Credit). Thanks to Low-Iron Low-E glass, those planning buildings don’t need to pick one over the other between bright spaces and cozy warmth inside.

The Hidden Danger: NiS & Spontaneous Breakage

Current setups for building walls use Fully Tempered Glass in many places because it offers solid power. Yet, it hides a flaw you can’t spot: spontaneous breakage. In upscale projects that aim to be landmarks, such a chance often proves too much to handle.

The Science of Spontaneous Failure

Even though making processes today aim for exactness, tiny bits of nickel might team up with sulfur to make Nickel Sulfide (NiS) spots inside. In the quick cool-down part of the toughening step, unstable high-temperature α-phase NiS inclusions get stuck fast in the glass material. As days turn into years, shifts in the air temperature around make those spots change to a firm β-phase NiS stage. They swell up by 2% up to 4% in size. For Fully Tempered Glass, the inner part sits under strong pull forces. So, this swell starts small breaks that snap the full sheet right away.

The Owner’s Nightmare: A Costly Game of Probability

Numbers from the building world point out that usual Fully Tempered Glass carries a break chance on its own of about 3‰ to 5‰. Picture a city tower holding 10,000 wall pieces. Over the whole time it stands, that adds up to 30 to 50 failures. The threat to safety goes beyond just that. The money side hits hard too. Swapping one piece in a tall wall setup costs a lot. It covers worker time, special lift gear, and blocking off streets below. Often, this runs 10 to 20 times more than buying the glass by itself. Owners face not only repair bills but also delays in use and possible claims from those hurt below.

The Limits of Heat Soak Testing (HST)

Heat Soak Testing (EN 14179) gets applied to cut down this issue. It works by breaking pieces with faults ahead of time. But it falls short of a sure 100% fix. On top of that, the added heat round stretches out wait times for delivery. Sometimes, it even brings stress easing or bends in how light passes through.

The Strategic Solution: Low-Iron Heat Strengthened Glass

Top projects call for both safe builds and nice looks. For those, Glasvue puts forward a “Dual Line of Defense” approach. This plan layers protection in smart ways to cover risks from the start.

1. The Inherent Purity of Low-Iron Glass

Low Impurity, Low Risk: Low-iron glass goes beyond just making things look good. It picks safety as a main goal too. Tough checks on base materials cut down iron levels. They also trim the starting points for NiS spots. When you go with Glasvue low-iron bases, you drop the flaw odds at the tiny building block stage. This happens way before the glass sees any heat in production.

2. The Structural Advantage of Heat Strengthening

Immunity to Spontaneous Breakage: Heat-strengthened glass builds up push on the outside face from 24–52 MPa. That push amount stays low enough not to spark from NiS swells. When mixed with the clean makeup of low-iron glass, it wipes out nearly all chances of breaks on their own.

Superior Flatness: This method cuts back on wavy marks from rollers. It gives a smooth shine like a mirror. Building shapes stay sharp and free from twists as a result.

Post-Breakage Residual Strength: Layered setups with heat-strengthened glass break into bigger bits. Those bits hold in place within the glue layer between. This setup offers key residual stiffness. It stops the full flop down like a soaked cloth that comes with regular toughened glass.

The Business Case for Low-Iron Glass

Developers and owners who keep an eye on ROI find Glasvue Low-Iron glass as a smart choice to build up property worth. It stands as more than a high-cost extra. Instead, it pays back through better appeal and fewer headaches down the line. Properties with this glass draw more interest and hold value longer in tough markets.

Rent Premium & Prestige:

Fancy office spaces and home areas rely on clear lines of sight as a big draw. Clear views without any green haze boost how the place comes across. This pulls in top-level renters. It also keeps more units taken at better prices over time.

Brand Identity:

Leading stores like Apple or Louis Vuitton and main company offices use the front face as their key sign. See-through clarity like crystals sends out a feel of clean setup, open doors, and smart tech use. It shapes how people view the brand right from the street.

Long-term Asset Value:

Cutting down on breaks that happen alone lets owners trim OpEx (operating expenses) by a good amount. They skip court fights and damage to their good name from glass drops. Over years, this keeps costs steady and builds trust with those who use the space.

Real-World Case Study

Project Background: This fine build sits in Australia and takes on heavy sun hits along with firm safety rules under AS 1288. The area’s bright light and changing weather test materials in ways that demand careful picks from the start.

The Challenge: The group behind it needed a way to stand strong against wind pushes and hold heat well. All this had to keep clear sight lines intact. Plus, it could not risk breaks popping up under the tough sun in Queensland. Balancing these needs took real thought on every part.

Glasvue Solution: A strong setup of IGU paired with Heat Soak Testing (HST). This mix handled the tough spots while keeping things safe and sharp to look at.

Configuration: 6mm (Tempered + HST) + 12A (Black Spacer) + 5mm (Low-Iron Tempered + HST). The layers fit together to seal air and take impacts without fail.

Aesthetic Detail: Inside, the 5mm Low-Iron glass kept colors true to life. The black aluminum spacer hid the backup seal from view. This created a plain, simple look that fit the whole plan just right.

Safety Assurance: The build plans asked for full tempering on the glass. So, Glasvue ran careful Heat Soak Testing across both layers. This cleared out any NiS threats and locked in safe use for the long haul.

The Result: They finished the job with not a single break after putting it in place. The front shows a clear, sharp face that matches the blue sky over Queensland in a perfect way. It stands as a strong example of how good planning pays off in real spots.

Conclusion

All the signs point straight to one thing. Blending Low-Iron Glass with Heat Strengthening or HST-tempered pieces where the weight calls for it makes the best path for current building fronts. This combo hits the sweet spot between style, safe holds, and smart energy flow. Builders can count on it to last through years of use while keeping the look fresh and the space welcoming.

Start Your Project with Glasvue

Window builders, wall fitters, and designers around the world should take note. Average glass can take the shine off your best building ideas. Choose better to let your work stand out strong.

Get in touch with our Worldwide Project Crew right now for:

No-charge advice on tech designs matched to your build steps.

Fine Low-Iron glass pieces to try out.

Shipping and move plans across the globe to make your material lines run smooth.

Glasvue: Redefining the Limit of Transparency.