When architects and builders venture into the sophisticated world of modern glazing, structural engineers frequently encounter a reality that feels somewhat backwards: 10mm + 10mm does not necessarily equal 20mm. In the specialized realm of laminated glass, the overall performance of the assembly is far more than just a basic addition of the glass layers. Instead, it is governed by a complex, somewhat hidden variable—the interlayer. Whether your project specifications call for Polyvinyl Butyral (PVB) or the much stiffer SentryGlas® (SGP), the material functions as a viscoelastic substance. This fundamentally means its ability to support structural weight shifts significantly depending on the ambient temperature and how long the load stays in place.

At GlasVue, we are firm believers that truly exceptional glazing design is born from an incredibly deep grasp of material science. This comprehensive guide will walk you through the “Effective Thickness Method,” the subtle impacts of viscoelasticity, and the specific reasons why choosing between PVB and SGP can either strengthen or completely undermine your structural engineering calculations.

1. Breaking the Core Concept: Why 10+10 ≠ 20?

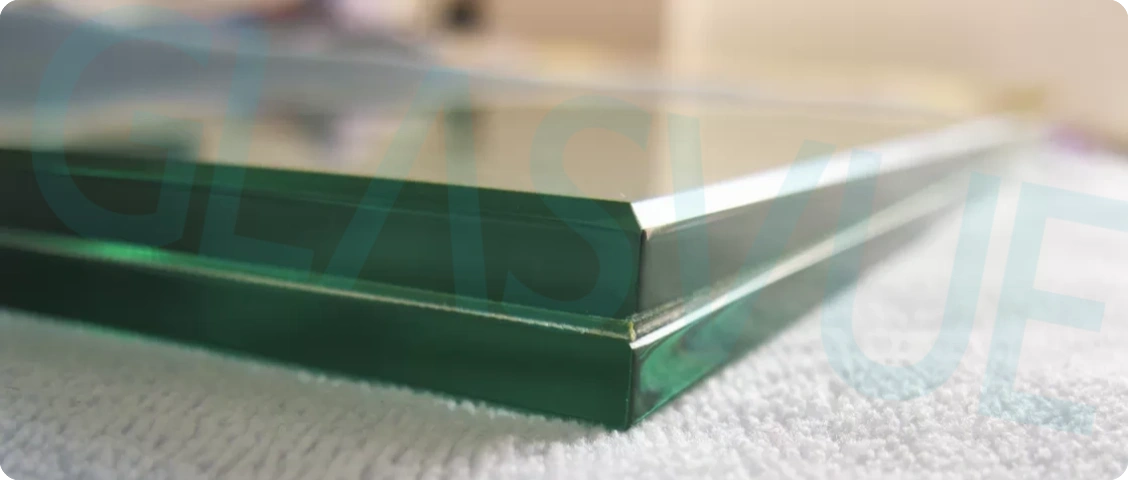

To accurately determine the true strength of a piece of laminated glass, we have to look far past the visible glass sheets and concentrate our attention on the shear transfer facilitated by the plastic interlayer tucked inside.

1.1 The Structural Modeling Dilemma

In the world of structural mechanics, a laminated glass panel exists somewhere between two different theoretical extremes:

- The Layered Limit (G ≈ 0):Picture two separate glass plates with a thin layer of slippery liquid soap rubbed between them. If you push down on them, the plates will slide back and forth against each other without any resistance. They bend as two independent units. In this particular scenario, the total strength is merely the sum of the two individual plates, but the overall stiffness is remarkably low.

- The Monolithic Limit (G ≈ ∞):Now, imagine those same two glass plates were perfectly melted and fused into one solid 20mm block. There is absolutely no sliding or “slip” between the layers. This setup provides the maximum possible stiffness and the highest capacity for carrying heavy loads.

- The Real-World Situation:Most actual laminated glass panels fall somewhere in the middle of these two extremes. The exact amount of coupling—or how well they work together—depends entirely on the Shear Modulus (G) of the specific interlayer material used.

1.2 The Essence of Viscoelasticity

The “hidden factor” that complicates things is that this Shear Modulus is not a steady, unchanging number. These interlayers are viscoelastic, which is a fancy way of saying their physical properties are a direct result of:

- Temperature (T):As the glass panel gets warmer under the sun, the plastic interlayer begins to soften and lose its grip.

- Duration of Load (t):A quick, three-second blast of wind is handled very differently by the material than a heavy snow load that sits on the roof for several weeks.

For an engineer, the source of frustration is quite obvious: you simply cannot utilize one single, static Young’s Modulus (E) to describe how the interlayer will behave. Instead, you are required to calculate a unique “Effective Thickness” for every single different load situation the building might face.

2. Deep Dive: The Effective Thickness Method

How exactly do we turn a complicated, multi-layered “sandwich” of glass and plastic into a set of numbers that an engineer can actually plug into a calculation? We utilize a strategy known as the Effective Thickness Method.

2.1 The Logic: Wölfel, Bennison, and ASTM E1300

The primary objective of this calculation strategy is to discover a single “equivalent” thickness (heff) that would result in the exact same amount of bending or stress as the real-life laminated section. The most vital part of this math is the Shear Transfer Coefficient (Γ).

This coefficient, Γ, typically stays between 0 and 1:

- If Γ is 0, the glass is essentially acting at the “Layered Limit” mentioned earlier.

- If Γ is 1, the glass is performing at the “Monolithic Limit.”

The basic conceptual formula used to figure out the stiffness looks like the following:

In this math, Is represents the physical distance between the center points of the glass layers. The specific value of Γ is decided by the physical shape of the panel, how thick the interlayer is, and—most importantly—the current Shear Modulus (G) of that interlayer.

2.2 Moving Beyond ASTM E1300

While the ASTM E1300 standard is the traditional rulebook for the industry, its Appendix X1 actually has some pretty major gaps. It was originally created mostly for glass that is supported on all four sides and carries a very even, uniform load across the surface.

In the creative world of modern architecture, however, we are frequently dealing with much more difficult setups:

- Cantilevered Balustrades:These are glass railings that are only held at the very bottom, with the top edge left completely free.

- Glass Fins:These are long, structural glass pieces that provide sideways support to massive building facades.

To tackle these tougher problems, GlasVue makes use of the Enhanced Effective Thickness (EET) method. This EET approach adds in a special “calibration” factor that accounts for various ways the glass is held (like the cantilevers mentioned) and different types of weight (like a heavy point load versus a light, even load), giving us a much more precise answer than the basic, bare-minimum codes.

3. The Showdown: PVB vs. SGP at High Temperatures

Heat is truly the “weak spot” for most laminated glass products. In many parts of the world, a glass wall that is sitting in the direct path of the summer sun can very easily reach a temperature of 50°C (122°F) or even higher.

3.1 The 50°C Benchmark

When the thermometer hits this level, the difference in how standard PVB and high-performance Ionoplast (SGP) behave is truly like night and day.

3.2 Shear Modulus Data Comparison

- Standard PVB @ 50°C (Long-term load):Under these hot conditions, the G value of standard PVB can crash down to less than 0.1 MPa. At this stage, the plastic interlayer is basically acting like a very thick, gooey liquid. The Γ coefficient essentially turns into 0. This means the glass falls back to that “Layered Limit,” resulting in huge amounts of bending and a very real danger of structural trouble if the glass wasn’t significantly over-designed to begin with.

- SGP (Ionoplast) @ 50°C (Long-term load):SGP is a much tougher and more rigid type of polymer. Even when it reaches 50°C, it manages to keep a G value that is usually higher than 100 MPa. Its Γ coefficient stays very close to 1. This ensures that the glass continues to work together as one single, solid unit.

3.3 Impact on Your Structural Calculation Report

When the team at GlasVue provides consulting for a new project, the type of interlayer chosen completely dictates how thick the glass needs to be:

- If using PVB:You might find yourself forced to use 12mm+12mm glass just to satisfy the rules for how much the glass can bend in the heat, primarily because the soft interlayer isn’t helping the structure at all.

- If using SGP:You could potentially get the exact same structural strength by using 8mm+8mm glass instead. By picking a much stiffer interlayer, you can reduce the total weight of the glass, which then lowers the cost of the metal hardware holding it up and shrinks the overall carbon footprint of your building.

4. Engineer’s Field Guide: Practical Application

4.1 When is SGP Mandatory?

Even though PVB is a fantastic choice for blocking out noise and creating basic safety glass, the SGP material is absolutely necessary for:

- Cantilevered Structures:This includes frameless glass fences where the glass absolutely must stay standing up straight even if one of the glass layers happens to break.

- Point-Supported Glass:This refers to designs where bolts, screws, or small clips create very high pressure in small spots, requiring a stiff interlayer to spread that stress out safely.

- High-Temperature Structural Members:Any glass part that needs to carry weight while sitting in a hot environment.

- Post-Breakage Stability:For glass that is installed over people’s heads (like skylights or glass ceilings), SGP ensures the broken pieces stay stiff and locked in place, preventing the glass from sagging like a heavy wet blanket.

4.2 How to Source Accurate G Values

It is very important that you do not just rely on generic or “guesswork” data. To produce a truly professional calculation, engineers need to ask for the Master Curves or the Time-Temperature Superposition (TTS) graphs directly from the companies that make the interlayers, such as Kuraray (who makes Trosifol®).

GlasVue works very closely with these specific data collections, and we choose the right G value based on exactly how long the load will be there:

- Wind Loads:We use the G value for a quick, 3-second burst at temperatures between 20°C and 50°C.

- Snow or Maintenance Loads:We look at the G value for a load that might stay for 30 days or even permanently.

5. Summary

The world of structural glass design is no longer just about looking up a quick number in a simple table. Instead, it has become a detailed exercise in the study of material science. By truly becoming an expert in the Effective Thickness Method and gaining a clear understanding of how interlayers change their behavior in the heat, engineers can develop building designs that are both incredibly daring and perfectly safe.

At GlasVue, we are dedicated to providing the high-level technical knowledge and the top-tier materials that are required to navigate these difficult calculations successfully. Whether you are in the middle of designing a massive glass skyscraper or a tiny, minimalist glass staircase, having a solid grasp of “Effective Thickness” is the absolute key to making your structure as efficient and safe as possible.

FAQ

Q: Am I able to use the exact same Effective Thickness for both my stress and my deflection calculations?

A: Unfortunately, the answer is no. In the most accurate engineering methods (such as the EET method), the effective thickness used for figuring out bending stress is slightly different than the one used for figuring out deflection. Calculating how much the glass will bend (deflection) usually requires a thickness based on stiffness, while figuring out if the glass will break (stress) requires a thickness based on strength to make sure the outer surface of the glass doesn’t go past its safe limits.

Q: How does the “Post-Breakage” condition change the way the Effective Thickness is calculated?

A: Generally speaking, the effective thickness is used when designing glass that is still perfectly intact (pre-breakage). However, if you are designing for a “post-breakage” situation where one or both layers have shattered, the math changes completely. For SGP, we calculate how much strength is left based on the plastic’s ability to act as a structural “bridge” between pieces. For PVB, the effective thickness basically disappears and falls to almost zero, meaning the design has to rely on the broken glass bits wedging together or being held up by the metal frame.

Q: Is there a really big price difference between PVB and SGP that I need to think about during the early design phase?

A: Yes, SGP is definitely more expensive per square foot than standard PVB material. However, you have to consider the “engineering value” which often makes up for the higher price. Because SGP is so much stronger, you can often use thinner glass (for example, using 8mm instead of 10mm). This makes the entire glass panel much lighter, which can lead to using smaller, cheaper metal supports and saving money on shipping and installation. At GlasVue, we always suggest looking at the total cost of the whole project rather than just looking at the price of the plastic interlayer by itself.