Overview

In today’s fast-changing world of building design, curved glass has become a key player. It mixes fresh looks with solid work. Flat glass is old news now. Curved glass brings smooth lines and natural shapes. These push past old limits. Architects can make standout buildings that grab attention and spark ideas. This post dives into curved glass details. We cover how it’s made. We look at its big effects on building styles. We spotlight Glasvue. This top provider of glass for buildings gives top curved glass for tough jobs. From fancy fronts to smart inside setups, Glasvue’s curved glass joins fine work with new tech. It fits what bold builders need around the globe.

Introduction to Curved Glass

Curved glass marks a high point in building materials. It lets form and use blend well. Its skill to fit tricky shapes opens many doors. Think wide covers or wavy walls. At Glasvue, we focus on making good curved glass. It follows world rules. This keeps it strong and able in many spots.

Manufacturing Processes of Curved Glass

Making curved glass uses smart ways. These mix care, size, and material health. Two main ways lead the field. Cold bending and hot bending each fit certain needs.

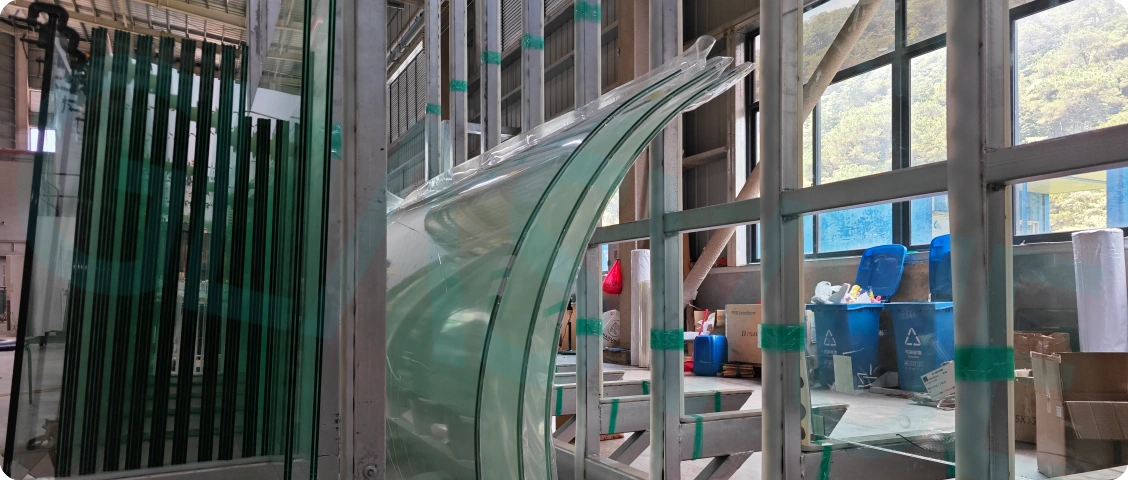

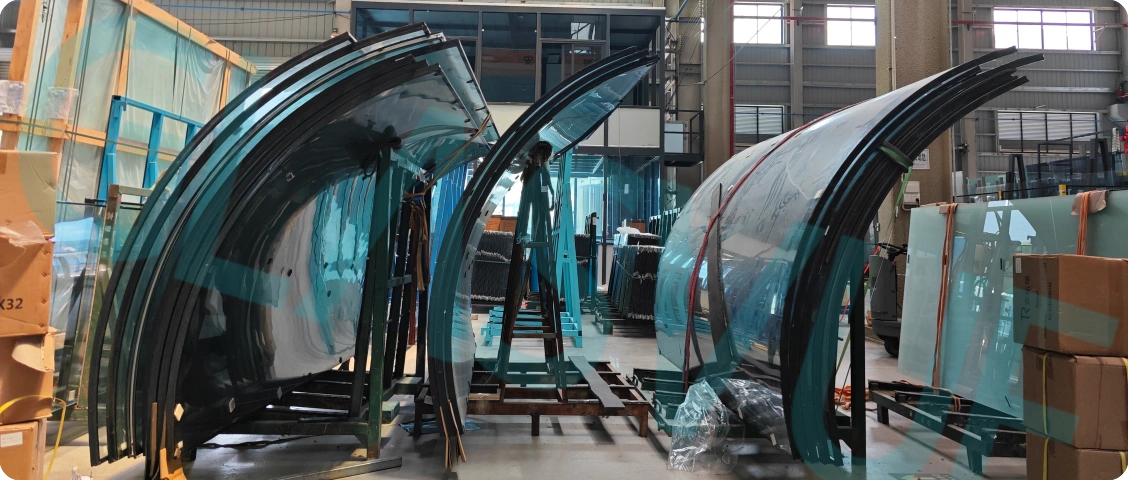

Hot Bent Glass

Hot bending heats glass to high warmth. About 600-700°C in special ovens. The glass softens. It shapes to detailed forms. Then it cools slow to ease inside pulls. This way allows big bends. Like two-way curves or round ball shapes. Key for art parts like tops or sided roofs. Glasvue uses top hot bending ovens. These have number controls for even work. They back bends from 300mm up. It takes more power. But Glasvue’s hot bent glass gives top bend freedom. Often picked for big-name setups. Where looks beat ease.

Impact of Processes on Performance (Strength, Transmittance, Reflection Control)

Picking the make way changes the end work of curved glass a lot. Strength grows with toughening. Glass cools fast here. It makes tight top stresses. This lifts hit hold by four or five times over soft glass. Glasvue’s cold and hot bent types can get this. They meet AS/NZS 2208, EN 12150, and ASTM C1048 rules.

Light pass stays strong for curved glass. Glasvue’s items keep over 90% light flow after bend. Low-iron mixes cut green shades. Reflection tune comes from layers like Low-E. These cut sun heat take by half. Yet keep good views. In hot bent glass, coats go on after shape. To skip peel off. This keeps long life. In all, these ways make glass that holds weather hits. It also helps green builds. By best use of day light and heat hold.

How Curved Glass is Changing Architectural Design Trends

Curved glass shifts building ways. It moves from stiff use to live, feel-full spots. By letting smooth switch from inside to out, it builds move and dive feel. This fits number shape rules. These use computer plans for natural forms.

From Straight Lines to Curves: The Evolution of Architectural Aesthetics

Long ago, modern stars like the Seagram Building showed clean straight lines. They put work over show. Late 1900s turned a corner. After-modern builders like Frank Gehry added curves. To stir feel and story. Now, curved glass boosts this turn. Seen in Zaha Hadid’s flow shapes. Glasvue backs this flow. We give bend glass that works with BIM tools. Building info models let plan bends on screen first. Before make. This opens big looks to more than top jobs.

Iconic Building Case Studies

Think of the Guggenheim Museum Bilbao. Its metal curves changed city growth. Curved glass could add clear in such plans. Near us, the Beijing National Stadium, or Bird’s Nest, used curved clear for its bone frame. It shows how bent panels share weight new ways. Glasvue helped like jobs. Like a bend office tower in Shanghai. Our hot bent warm glass units gave sight thrill and save power. Cut cool heat needs by one fifth. These stories show curved glass’s part in making spots that mix art with build skill.

![]()

The Evolution of Curved Glass in Architectural Trends

As number make tools grow, curved glass keeps changing. From hand-made one-offs to batch parts. Glasvue sees this path. We put cash in test for mix ways. That join cold and hot bend for mix curves. This change not just sharpens looks. It fixes green needs too. Glass that can reuse cuts build carbon foot.

We see more use in smart cities now. Curved glass helps with sun paths. It lets in right light at right times. Builders use it to cut power bills. In hot spots, it blocks too much heat. In cold areas, it traps warmth inside. This makes homes and offices comfy year-round. Plus, it looks great. People love the flow feel. It makes spaces feel open and free.

Glasvue’s Curved Glass Solutions

At Glasvue, our curved glass line is built for many uses. It draws on years of know-how. To give fixes that lift build dreams. We put new first. Every panel hits hard quality marks.

Curved Toughened Glass – Enhanced Impact Resistance

Glasvue’s curved toughened glass gets heat tough after bend. It breaks into small, dull bits on hit. This cuts hurt risks. This type has four to five times the hold of plain glass. Great for busy spots like game house wraps. Our own cool way skips sight twists. Even in bends under 500mm.

Laminated Curved Glass – Enhanced Glass Safety

Safe comes first. Our laminated curved glass puts plastic films like PVB or SGP between sheets. It holds bits if break. Comes in cold or hot bent. It meets EN 356 for safe clear. Fits public fronts. Glasvue’s made-up layer backs color films. For look boost without lose UV hold.

Insulated Curved Glass – Improved Sound and Thermal Insulation

For work-strong plans, Glasvue’s insulated curved glass units, or IGUs, have shut air or gas fills. Like argon. This hits U-values near 0.8 W/m²K. For top heat hold. Sound block scores over 35 dB. Best for city noise cut. These keep bend health. Back uses from air spot ends to home open rooms.

We craft these units with care. Each one seals tight. No leaks over time. That means steady work for years. Builders pick them for green points. Less heat loss means less fuel burn.

Manufacturing Precision and Forming Capabilities

Glasvue’s new plants have number control cuts for ±0.5mm fits. And 3D scans for form truth. We take curves up to 10 meters wide. Forming skills cover one-way rounds to many-way balls. This lets builders push make bounds.

Our team tests each step. From raw sheet to end shape. This cuts flaws. It makes sure every piece fits the plan.

Key Advantages of Curved Glass Offered by Glasvue

Glasvue’s curved glass shows clear wins. It slips into new jobs smooth. And gives real worth you can measure.

Multiple Bending Forms

We give many bend types. Like cold bent, hot bent, two-way bends, round tubes, and top shapes. These meet varied wants. From smooth wall wraps and big roof lights to live fronts. Your plan stays full.

Superior Structural Integrity and Durability

Made for long run, our curved glass takes wind push up to 5 kPa. And heat swings from -40°C to 80°C. New edge fixes stop tiny cracks. This stretches use past 30 years in rough weather.

We use strong stuff. It stands rain, sun, and wind. No fade or weak over time.

Safety and Strength Combined

All Glasvue curved glass can tough or layer. For high hit hold and safe break traits. Meets AS/NZS, EN, and ASTM world safe rules. Gives calm for tall and open setups.

Composite Functional Design

Flex marks our way. Mix curved glass with shut, layer, Low-E, paint, or heat-back coats. For full work. Get sound hold, heat rule, fire hold, and UV block in one sheet. Best build wraps for LEED green tags.

These adds make glass do more. One panel can cut noise. It can save heat. And look sharp too.

High-End Customization Capabilities

Glasvue gives full help. From idea plan and stress checks to true make and quality check. Our group works with builders. To make one-kind dreams real. Sure smooth job run.

We talk early. We hear your needs. Then we draw it out. Test it on comp. Make sure it works before build.

Diverse Applications of Curved Glass in Modern Projects

Curved glass goes past looks. It fixes true issues over sizes.

Facades and Curtain Walls for Iconic Buildings

In big-name builds, curved glass fronts make shine skins that change with light. Glasvue’s fixes powered the wave wrap of a Dubai mix tower. Layer units balanced clear with blast hold. Drew one million eyes a year.

These fronts pull crowds. They make buildings talk. People stop and stare. It boosts city vibe.

Interior Elements and Custom Installations

Inside, curved walls and show cases add shape fun. For a high-end hotel front room in Sydney, our cold bent splits with Low-E layers boosted sound. And poured day light in. Lifted guest feels.

We see this in shops too. Curved shows draw buyers. In homes, it makes rooms flow better. No hard stops. Just smooth moves.

Curved glass fits old spots too. Like church tops or school halls. It brings new life. Without big change.

Expert Services and Next Steps with Glasvue

Team up with Glasvue. You get a full help web.

Comprehensive Consultation and Installation Support

Our pros give free talks. Like spot checks and test models. From ship to checked set-up, we make sure no hitches. Cut down time off.

We guide you step by step. Pick the right bend. Check it fits your frame. Then set it safe.

Contact Us for Tailored Curved Glass Projects

Set to bend your next build? Hit up Glasvue now. For made-for-you bids and plan meets. Check our site. Start turn your build wishes to real.

We wait to hear from you. Let’s make something great.

FAQs

Q: What sets Glasvue’s curved glass make ways apart from others?

A: Glasvue stands out in care and flex. We do cold and hot bend with fits under ±0.5mm. Our built-in tough and layer skills give better hold and safe. All meets world rules like AS/NZS and EN.

Q: How does Glasvue’s curved glass help green building?

A: By mixing Low-E layers and shut units, our curved glass cuts power use up to three in ten. Through better heat work and day light. Backs green tags like LEED. Cuts world hit.

Q: Can Glasvue make curved glass for one-kind job needs?

A: Yes. We give full make-up. From two-way bends for tricky shapes to work adds like fire-hold layers. Backed by plan checks and spot help. For smooth run.