Over the last three decades, modern building design has seen a major shift. It moved from fixed shading ideas to active performance features. In this new era, building envelopes are no longer just physical barriers that shield occupants from harsh weather. Instead, they act as dynamic “skins” that manage energy flow between the controlled indoor space and the outdoor climate. For international door, window, and curtain wall makers, architects, and project owners, picking glass has evolved. It is no longer a simple aesthetic choice. Now, it is a vital engineering decision that shapes the building’s carbon footprint, the size of its mechanical systems, and its long-term viability.

The old limits of glass—high heat conduction and uncontrolled solar heat gain—created a “transparency dilemma.” Architects often want walls to feel less solid. They seek floor-to-ceiling views that link people to nature or city scenes. However, HVAC engineers face a tough thermal reality. Standard clear glass acts like a heat leak in the building’s insulation. In summer, it lets in a lot of solar heat. In winter, it allows indoor heat to escape. The fix for this dilemma comes from the precise use of Low-E coating technology.

This report serves as a detailed technical guide and strategic roadmap. It helps stakeholders navigate the challenges of selecting Low-E glass. Tailored for global players—especially Glasvue’s clients—it offers the scientific insight needed to specify high-performance glass systems. By using advanced spectral selectivity, grasping the differences between magnetron sputtering and online pyrolysis, and adjusting specs for specific climate zones, teams can achieve both stunning aesthetics and strong energy efficiency.

Spectral Principles of Low-E Glass

To choose glass wisely, you first need to understand the basics of solar radiation and heat transfer. The term “Low-E” is common in the field. Yet, the thermal mechanisms behind it are often misunderstood. The power of Low-E coatings stems from quantum mechanics and electromagnetic spectrum principles.

Electromagnetic Spectrum and Solar Energy

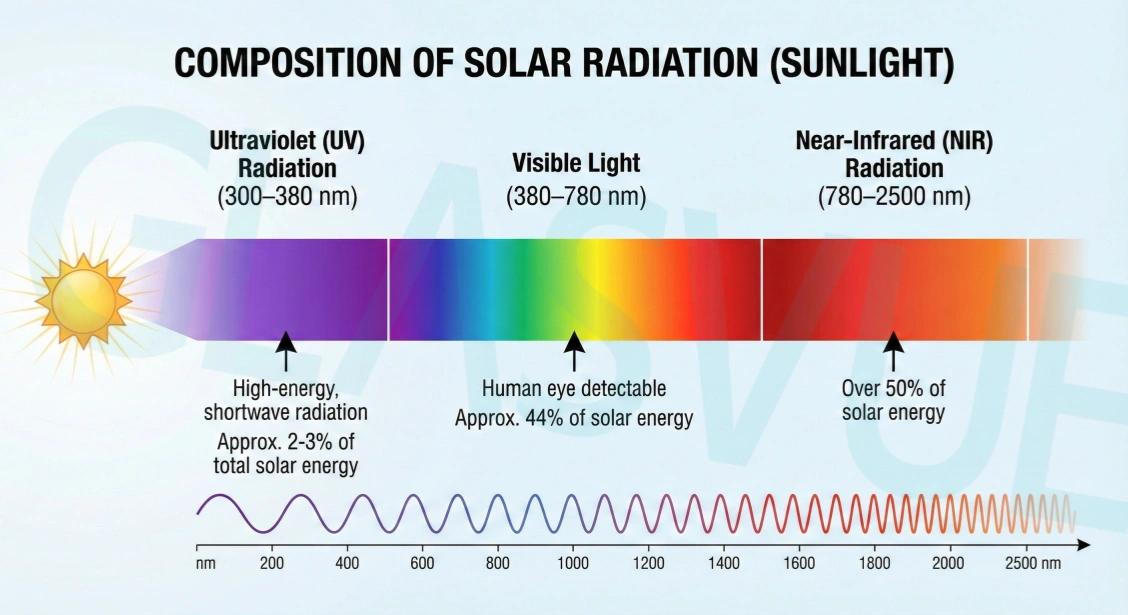

Solar energy reaching Earth’s surface consists of light in specific wavelengths. For building performance, it splits into three key bands.

- Ultraviolet (UV) radiation (300–380 nm): This high-energy, short-wave radiation makes up just a small part of total solar energy (about 2-3%). But it causes fading in indoor furniture, floors, and artwork. It boosts cooling loads without offering any visual benefits.

- Visible light (380–780 nm): This is the band the human eye can see. It accounts for roughly 44% of solar energy. High-performance glass aims to maximize transmission here. That promotes daylight autonomy—the ability to light spaces without artificial lights. As a result, it cuts electricity use and supports occupants’ natural sleep-wake cycles.

- Near-infrared (NIR) radiation (780–2500 nm): This band exceeds 50% of solar energy. It is invisible to the eye but feels like heat. In cooling-focused climates, NIR is an unwanted intruder that raises air conditioning needs. In heating-focused areas, it can serve as a passive heat source.

Glass faces a core challenge: spectral selectivity. This means acting as a filter that lets visible light pass while blocking UV and NIR. Standard clear float glass lacks this selectivity. It transmits light and heat almost equally. Low-E coatings add this ability. They effectively “slice” the spectrum to allow light but block heat.

Coating Structure Breakdown

Today’s Low-E coatings are not simple single layers. They are complex nanoscale stacks with multiple layers. Each layer handles specific optical or structural tasks. A typical “soft coat” stack might have 12 to 18 layers. Yet, its total thickness is less than a thousandth of a hair’s width.

- Functional layer (silver): Silver (Ag) is the main metal due to its top-notch conductivity and selectivity. It reflects infrared radiation while staying highly transparent to visible light. The number of silver layers (single, double, or triple) sets the level of spectral selectivity.

- Dielectric layers (ceramics): Layers of zinc oxide, tin oxide, or silicon nitride sit between silver ones. They work as anti-reflective coatings. Through optical interference, they boost visible light transmission and cut down on silver’s mirror-like reflections.

- Barrier/protection layers: Thin layers of titanium or nickel-chromium (NiCr) are deposited to shield the silver from oxidation during sputtering and later heat processing. These ensure the stack’s durability and lifespan inside insulated glass units (IGUs).

Manufacturing Processes: Online Pyrolysis vs. Magnetron Sputtering

The performance traits of Low-E glass tie directly to its production method. For overseas buyers—from Southeast Asian fabricators to North American developers—knowing the difference between “hard coat” and “soft coat” is key. It ensures durability and performance fit.

Online Pyrolysis Deposition (Passive Low-E / Hard Coat)

The pyrolysis process happens “online” during float glass production. As the molten glass ribbon passes through the tin bath and annealing lehr at over 600°C, chemical vapors (often tin oxide) are sprayed onto the surface. The high heat causes a covalent bond with the glass. This creates a ceramic-like fusion.

Advantages:

Outstanding Durability: The coating is essentially part of the glass. It resists scratches and oxidation well.

Processing Ease: Hard coat glass handles, cuts, tempers, and laminates like regular float glass. Importantly, it needs no edge deletion or sealing in IGUs. So, it suits single-pane uses, such as storm windows.

High SHGC: Pyrolysis coatings often show higher solar heat gain coefficients (SHGC). They work great in heating-dominant climates where free solar heat is welcome.

Disadvantages:

Higher Emissivity: Emissivity typically ranges from 0.15 to 0.30. That is much higher than soft coats. As a result, U-values suffer.

Haze: The coating’s crystal structure can cause slight optical haze. You might notice it under direct sunlight.

Offline Magnetron Sputtering Vacuum Deposition (Solar Control Low-E / Soft Coat / MSVD)

This process takes place “offline,” after glass making and cutting. The glass passes through a large vacuum chamber. Magnetron tubes create a plasma glow discharge. Ions in the plasma strike targets (like silver or zinc). This ejects atoms that deposit in precise, even layers on the glass surface.

Advantages:

Superior Performance: MSVD enables pure silver deposition. It achieves emissivity as low as 0.02. That delivers the lowest U-values and top spectral selectivity.

Optical Clarity: The coating has almost no haze. It offers a neutral look and high visible light transmittance (VLT).

Versatility: Makers like Glasvue can fine-tune stacks for specific aesthetics (blue, gray, bronze) and exact performance ratios (double silver vs. triple silver).

Disadvantages:

Fragility: The silver layers can oxidize easily or get damaged physically (scratches). So, soft coat Low-E cannot face air exposure. It must seal inside IGUs or become laminated glass. It does not work for single panes.

Processing Needs: Fabricators must remove coating from edges before sealing. This ensures the primary sealant bonds directly to glass. It prevents moisture entry and corrosion.

For premium commercial projects, curtain walls, and luxury homes with strict energy codes, offline Low-E glass is often the best pick. Glasvue focuses on these high-performance sputtered products. They meet global energy standards.

Core Performance Metrics for Low-E Glass

To specify the right glass, stakeholders must know key metrics defined by groups like NFRC (National Fenestration Rating Council) and IGCC (Insulating Glass Certification Council). These form the basis of data sheets from makers like Glasvue.

Visible Light Transmittance (VLT / Tvis)

VLT measures the percentage of visible solar spectrum (380–780 nm) passing through the glass system. For commercial daylighting glass, it usually falls between 40% and 70%.

Implications: Higher VLT cuts the need for artificial lighting. But it can increase glare risks. Managing glare often requires interior shades, which block views. Finding the “sweet spot”—around 50-60% VLT for offices—is essential.

Solar Heat Gain Coefficient (SHGC)

SHGC gauges the fraction of solar radiation entering through windows. It includes direct transmission and heat re-radiated inward after absorption.

Range: 0 to 1.

SHGC < 0.25: Excellent solar control. Vital for hot climates (Mexico, Middle East) and west-facing facades.

SHGC > 0.50: High solar gain. Ideal for cold climates (Canada, Scandinavia) in passive solar heating.

U-Value (Thermal Transmittance)

U-value measures the rate of heat transfer due to indoor-outdoor temperature differences. Lower values are better.

Single-pane glass: ~5.8 W/m²·K.

Standard IGU: ~2.7 W/m²·K.

Glasvue Low-E IGU (argon-filled): ~1.0 – 1.6 W/m²·K, based on the coating.

Advanced Coating Tiers: Single Silver, Double Silver, and Triple Silver

In soft coat Low-E, “silver” drives spectral selectivity. Glasvue offers products across the full silver range. Each targets specific cost-performance levels.

Single Silver Low-E

Structure: One silver stack.

Traits: Big improvement over plain glass. But spectral selectivity is limited.

Performance Data: VLT ~75%, SHGC ~0.29-0.56.

Best Uses: Residential projects in cold climates (gains some solar heat). Or budget-conscious commercial jobs with deep overhangs.

Double Silver Low-E

Structure: Two silver layers separated by a dielectric.

Traits: The current standard for commercial glass. It balances performance and neutral looks.

Performance Data: VLT ~72%, SHGC ~0.26-0.44.

Best Uses: Mixed climates (Shanghai, New York, Paris) for offices, hotels, and retail. It blocks much heat without darkening rooms.

Triple Silver Low-E

Structure: Three silver layers. This demands advanced sputtering cathodes for even layers and adhesion.

Traits: The highest spectral selectivity.

Performance Data: VLT ~41-63%, SHGC < 0.29.

Best Uses: Hot climates (Dubai, Southeast Asia, U.S. South) for large curtain walls (window-to-wall ratio > 60%). It lets architects use high-transparency glass without creating a “greenhouse” inside.

Strategic Selection: Aligning Glass with Climate and Orientation

The “right” Low-E glass is not fixed. It depends on the project’s location and orientation. Glass suited for Moscow could fail in Mexico City.

Cooling-Dominant Climates (Hot)

Regions: Southeast Asia (Vietnam, Thailand), Middle East (UAE), South China, Mexico, U.S. South.

Challenges: Blocking solar gain is the top priority.

Glasvue Recommendation: Triple silver Low-E glass. Focus on low SHGC (< 0.25). U-value matters too, but SHGC comes first.

Design Tips: Pair with body-tinted glass (gray, blue) and Low-E. This further lowers SHGC and controls glare in bright settings.

Heating-Dominant Climates (Cold)

Regions: Northern Europe, Canada, North China, Russia.

Challenges: Retaining indoor heat is crucial. Gaining free solar heat adds value.

Glasvue Recommendation: Prioritize low U-value (center-of-glass < 1.1 W/m²·K). Then aim for moderate SHGC (0.40 – 0.55) to let winter sun warm interiors (passive solar heating). Combine with argon fill or triple glazing for U-values near 0.6 W/m²·K.

Mixed Climates

Regions: Central Europe, U.S. Midwest, Central China.

Challenges: Balance summer cooling and winter heating.

Glasvue Recommendation: Double silver Low-E. Balanced SHGC (~0.35) prevents summer overheating. At the same time, it does not fully block winter warmth.

Glasvue: Your Manufacturing Partner for Global Projects

In the busy glass processing market, Glasvue stands out. It is more than a supplier. It is a vertically integrated technical partner. Based in Zhaoqing, China, the company runs a modern factory over 20,000 square meters.

Strong Capacity and Delivery Reliability

Glasvue has fully upgraded its manufacturing. The factory moved to a new site in Dinghu, Zhaoqing, Guangdong. The area now exceeds 20,000 square meters. This move builds a true “efficient automated glass processing enterprise.”

Our production lines reach 85% automation. This level is key for product consistency, especially in large export orders. It means high-precision machines control everything from cutting and edging to coating and assembly. Human errors drop to a minimum.

With the new scale, Glasvue handles high throughput. It secures delivery timelines for major global projects.

Annual capacity for tempered glass reaches about 1.2 million square meters.

For IGUs, it is about 300,000 square meters per year.

Laminated glass capacity hits about 120,000 square meters annually.

This setup ensures Glasvue delivers on time. It avoids huge penalties and losses from delays in large curtain wall projects.

Global Compliance: Rigorous International Quality Standards

For any building glass firm entering international markets, certifications are the only real proof of quality. Glasvue products hold several top global certifications.

As the key endorsement for North America, Glasvue has IGCC certification. Products follow ASTM E2190 standards strictly. This involves tough third-party tests for IGU seal durability, argon retention, and moisture resistance. It meets non-negotiable North American demands for energy and longevity.

Our safety glass also earns certifications like China’s mandatory CCC, U.S. ANSI Z97.1-2015, European EN14449 (laminated glass), and Australian/New Zealand AS/NZS 2208/4666. These confirm Glasvue meets the strictest building codes worldwide in safety, performance, and processes.

Glasvue (GLASVUE) commits to being your reliable technical partner for global projects—efficient in delivery and excellent in quality.

Conclusion

Selecting Low-E glass is the most critical single choice in building envelope design. It blends physics (spectral selectivity), manufacturing (soft coat quality control), geography (climate tuning), and trust (maker certifications).

Glasvue is the perfect partner for this complex journey. With industrial power for bulk orders, automated precision, and design insight shown in building simulations, they bridge Chinese manufacturing efficiency and global architectural goals.

Get Glasvue’s Help

Do not leave your building performance to chance. Whether specifying high-rise curtain walls in Dubai or luxury homes in Vancouver, Glasvue’s engineering team is ready to optimize your glass picks.

Partner with Glasvue now for:

Thermal stress analysis: Ensures glass won’t crack under heat loads.

Custom optical calculations: Perfectly balances your VLT and SHGC.

Project-specific samples: See transparency and color firsthand before buying.