Patterned glass, once a charming feature of old-style designs, now sees a strong comeback in today’s building scenes. From simple office dividers to elegant home spaces, the need for surfaces that mix natural light with seclusion grows steadily. Still, for experts in the window and door field, picking the correct patterned glass goes beyond looks—it calls for solid knowledge of safety rules, handling methods, and supply dependability. This overview works to connect creative ideas with practical facts, giving builders, site leaders, and plant managers the clear details and buying tips required to carry out big jobs with assurance.

What is Patterned Glass?

Definition

Patterned glass, also called figured, textured, or rolled glass, is a kind of see-through decorative glass marked by clear patterns or surfaces pressed into one or both sides. Unlike regular clear float glass, which lets you see through clearly, patterned glass spreads out light, offering different levels of hiding while letting plenty of natural light fill the area. This special “see-through yet not clear” trait turns it into a key item in building plans where seclusion and style need to work together.

Process

Making patterned glass mainly uses the Rolling Process. In this approach, hot glass flows between two metal rollers. One or both rollers carry a set pattern or surface carved in. As the glass moves through the rollers in high heat, the pattern gets pressed in lasting way onto the side before it goes into the annealing lehr for steady cooling. This old but accurate way lets makers produce even, good-quality surfaces in large batches, making sure each piece fits the tight look standards of current building work.

Why Architects and Designers Choose Patterned Glass

The Perfect Balance of Light and Privacy

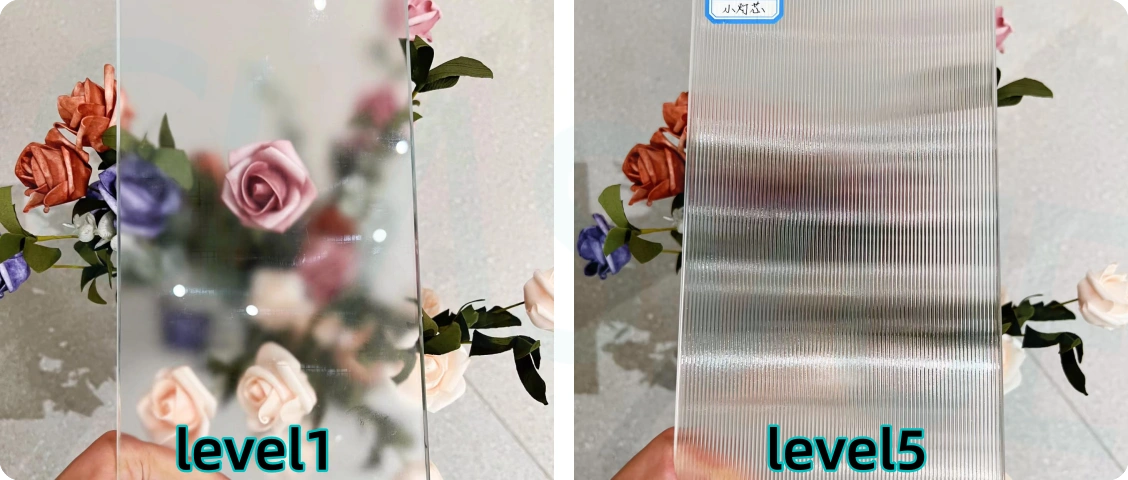

In today’s building styles, finding a way to capture natural light while keeping personal or work seclusion ranks as a top planning issue. Patterned glass handles this through its side texture that breaks up coming light beams. In tech terms, this gets checked by the “Obscurity Level,” often scored from 1 to 5. A Level 1 design (like Satin) gives light bending with good sight, but a Level 5 design (like Small Reed) offers full seclusion by fully hiding forms behind the glass. This spreading action cuts out bright flashes and warm areas, filling the inside with a gentle, even shine that regular clear glass fails to match.

Redefining Interior Partitions and Spatial Design

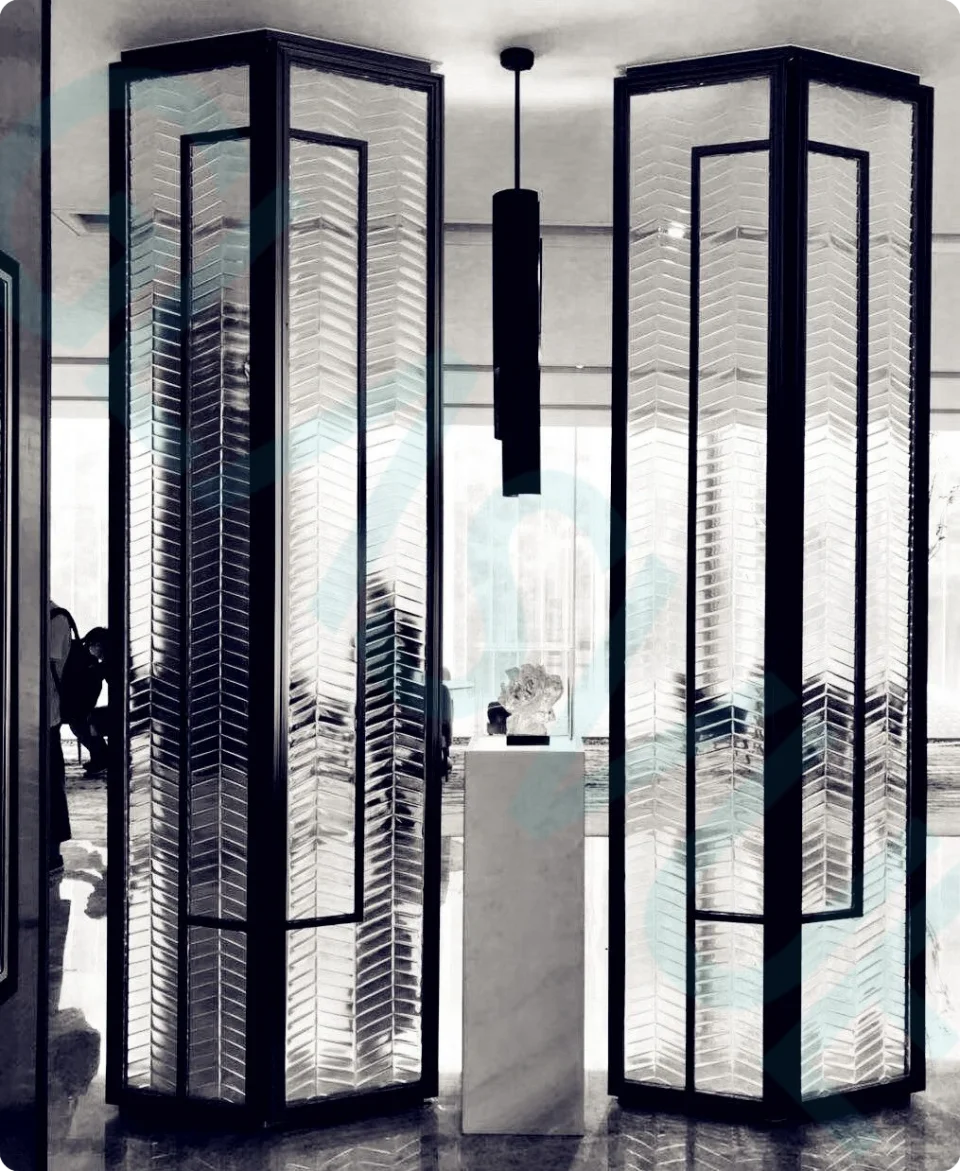

Past its basic use, patterned glass now acts as a strong aid for shaping inside styles. Regular clear glass can seem chilly or too plain in wide office or home setups. On the other hand, patterned glass brings tactile depth and visual rhythm. By making levels of fuzzy movement and crossing surfaces, it changes a plain space splitter into a smart style center. Whether in smooth office booths, sliding doors, or home screens, these surfaces end the plain look, adding a feel of high class and made care to the spot. It lets planners divide zones without solid walls, keeping an open layout sense while adding a touch of smart puzzle.

Popular Textures and Material Selection

Moru (Fluted/Reeded Glass) – The Minimalist Favorite

Moru glass, often known as fluted or reeded glass, has gained quick fame to stand as the top pick for simple building styles. Its main upright lines make a steady, straight fade that nicely hides people while stretching the sight height of a space. This “lengthening” result fits it well for full-wall dividers and current sliding doors, as it builds a sense of tallness and openness. Past its upright lines, Moru glass works well with man-made light, changing office booths and storage into shining, surfaced parts that add a level of now luxury without filling the area too much.

Nashiji, Raindrop, and Flora – Classic Textures Reimagined

As styles change, old designs like Nashiji (sand-style surface), Raindrop, and Flora stay vital for jobs needing strong hiding and a mild-focus look. Nashiji, for one, gives a soft, small-grain side that hits an Obscurity Level of 4 or 5, turning it into a key part for business bath dividers and clinic watch windows where seclusion stands firm. Raindrop and Flora surfaces, though, bring a more natural, style touch that copies real items. These designs often get fresh takes in now business halls and home damp spots, where they break strong sun into a soft, no-set shine, making a calm setting while well hiding mess or back movement.

Low-Iron vs. Clear Base Glass

One of the key choices for business buyers and builders is the base glass type: Low-Iron (Ultra-Clear) against regular Clear glass. Standard clear glass holds more iron oxide, which adds a clear green shade, easy to spot on edges or in deep surfaces like Moru lines. For top jobs where color evenness and top light passage matter most, Low-Iron Patterned Glass stands as the better pick. By cutting the iron a lot, this “Ultra-Clear” choice removes the green shade, leading to a bright, gem-like end that boosts the sharp feel of the surface. This makes sure white walls stay white and the planned color set of an inside plan holds, giving a high-class, smart look that standard clear glass just misses.

Technical Processing: Ensuring Safety and Quality

Precision Tempering of Textured Surfaces

A widespread wrong idea in the field holds that patterned glass can’t get toughened well because of its bumpy side. At Glasvue, we clear this up by using modern convection tempering furnaces set just for surfaced glass. The main issue sits in handling the cooling speed; since the “low spots” and “high spots” of the design cool at varied rates, exact air force handling proves key to skip side flaws or sudden breaks. Our toughened patterned glass hits a surface compression strength over 90MPa, making it fit world safety rules (such as ANSI Z97.1 and AS/NZS 2208). Once toughened, the glass grows 3-5 times stronger than regular cooled glass, fitting it safe for busy business dividers and doors.

Safety First: Patterned Laminated Glass

For jobs needing higher safety—for spots like office rails or break-in stop dividers—Patterned Laminated Glass serves as the go-to fix. By joining a surfaced glass piece with a clear glass piece via a PVB or strong SGP layer in between, we build a mixed setup that gives sight seclusion and holds build strength. Even if it breaks, the glass bits stick to the layer, stopping risky pieces from dropping or hurting people. This setup also brings better UV block (stopping up to 99% of bad rays), making it a flexible pick for fancy business insides.

Insulated Glass Units (IGU) for High-End Windows

As building power rules get tougher, makers often wonder how to mix the charm of patterned glass with strong heat work. The answer rests in our Textured Insulated Glass Units. To hit best power savings, we put Low-E (Low-Emissivity) layers on the smooth side of the patterned glass (often on the #2 side of a two-layer unit). This lets the unit send back infrared heat while the surfaced side gives the wanted look and seclusion from out or in. By mixing patterned glass with an argon-filled space and Low-E tech, we reach much lower U-values and SHGC (Solar Heat Gain Coefficient), making sure the building stays power-smart without losing its special style mark.

Manufacturing Excellence for Bulk Orders

For big business jobs and world window plants, the main hurdle in getting patterned glass isn’t only cost, but consistency. When a job calls for thousands of square meters of fluted glass, any change in design match or surface depth can lead to big sight differences once the glass sits in many window frames or dividers.

At Glasvue, we focus on exact making for large buys. Our tech group makes sure Pattern Alignment by tightly watching the rolling direction in the making steps. This means that when several glass sheets sit next to each other, the lines match just right, building a smooth and pro look. On top, we use strict Texture Depth Control. By checking roller force and glass heat right then, we promise that every group keeps an even surface thickness, making sure steady hiding levels and light passage over the whole building. This drive for making strength cuts extra work for our business partners and brings a perfect end for top jobs.

FAQs

Q: Which patterned glass provides the highest level of privacy?

A: Privacy gets checked by the Obscurity Level (1-5). For top privacy, we suggest Level 5 patterns such as Small Reed or Nashiji . These surfaces strongly spread light and fully hide forms, fitting them well for baths and private office spots.

Q: Are there any size or thickness limitations for tempered patterned glass?

A: Most of our patterned glass goes from 4mm to 12mm in thickness. While we can toughen most surfaces, very deep or detailed designs may face set size limits to keep even stress spread. In general, we handle sheets up to 2440mm x 3660mm, but we advise talking to our tech group for special big needs.

Q: How should I clean and maintain patterned glass?

A: For the smooth side, regular glass cleaners and a soft cloth work fine. For the textured side, we suggest a soft-bristle brush or a microfiber cloth to clear dust or dirt stuck in the lines. Skip rough pads or strong chemicals that might mark the side or harm the glass layer (if Low-E sits on).

Elevating Design Through Technical Expertise

Patterned glass goes beyond a style piece; it serves as a smart building aid that blends light, seclusion, and safety. As now styles turn to surfaces that stir feeling and size, picking a teammate with the know-how to toughen, layer, and seal these sides proves key for job win. At Glasvue, we hold that each job forms a team path. Our aim stays to turn your idea plans into build truths without cut. Whether you face hard safety needs or hunt bulk evenness for a world launch, our tech advisors stand ready to back your view. Check our touch sample set now or contact our group to talk how we can add exact-made surface to your next job.