Introduction

Glass is a huge part of today’s building designs and green architecture. It makes buildings look cool and awesome. Plus, it helps save energy and keeps rooms cozy. Among the many kinds of glass out there, Low-E glass and float glass are super popular. Both work like clear walls separating a building’s inside from the outside. But they’re really different when it comes to saving energy. This article digs into how Low-E glass compares to float glass. It’s here to help builders, architects, and homeowners choose the perfect option for their projects.

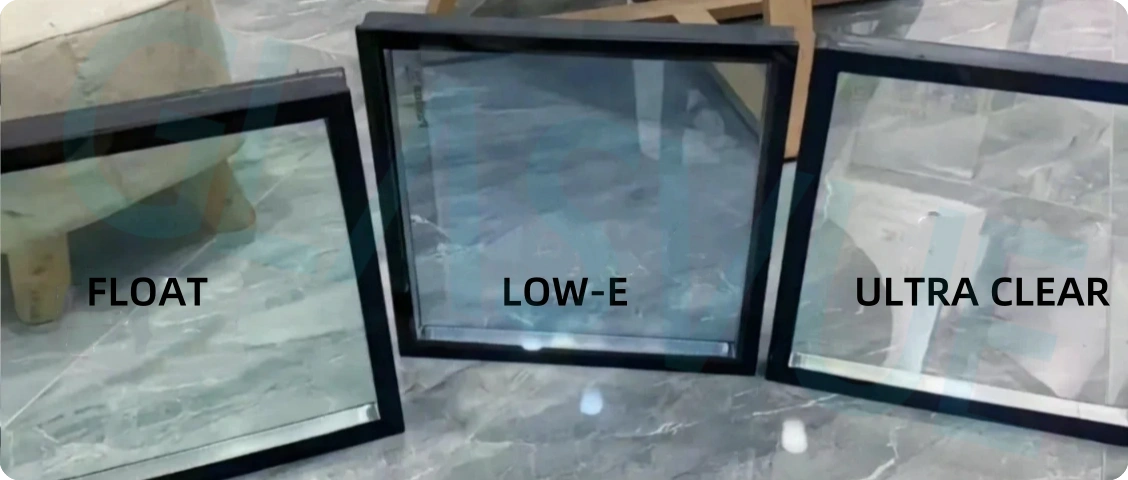

Low-E Glass and Float Glass: Core Differences

Composition and Manufacturing Process

Float Glass

Float glass is the simplest and most common glass used in buildings. It’s got a smooth, flat surface. It’s also even in thickness. But it doesn’t do a great job at blocking heat, cutting noise, or saving energy. That’s why it’s often just a starting point. People process it more, like making it stronger, layering it, insulating it, or adding a Low-E coating, to meet bigger building needs.

Low-E Glass

The special thing about Low-E glass is its low-emissivity coating. This coating deals with infrared and ultraviolet rays to boost insulation. Low-E glass comes in two types, based on how the coating gets added:

- Online Coating: Metal oxide layers are put on the glass during production in really hot conditions. The coating sticks tight to the glass. This makes it tough and awesome for single-pane use.

- Offline Coating: After float glass is made, layers of metal or metal oxides are added in a vacuum process called magnetron sputtering. This gives fantastic insulation but is more fragile. It’s usually used in insulated glass units (IGUs) or layered glass.

Optical Performance Differences

Visible Light Transmittance

- Light Transmission: Regular float glass lets 80%–90% of light pass through. It’s super clear but not very flexible. Low-E glass, because of its coating, usually lets less light through than float glass. But you can pick high, medium, or low light passage. This lets you balance natural light with energy savings.

- Reflectance/Color Tone: Float glass has no coating. It reflects just a bit of light and looks plain and clear. Low-E glass, with its metal or metal oxide coating, reflects more light. It might show soft blue, green, or gray colors, depending on the coating. This adds a cool, stylish vibe to building designs.

Thermal Performance Differences

Solar Heat Gain Coefficient (SHGC)

The SHGC tells you how much solar heat gets through glass. Bigger numbers mean more heat comes inside. Float glass doesn’t block much heat. Its SHGC is usually 0.70–0.80. Most solar heat goes right through. Low-E glass has a coating that pushes back infrared heat. It controls how much heat comes in. Its SHGC is 0.25–0.50, depending on the design. This cuts down heat and saves energy.

U-Value (Heat Transfer Coefficient)

The U-value checks how easily heat moves through glass. Smaller numbers mean better insulation. For the same 6+12A+6 structure, the U-value of float insulating glass is typically around 2.8–3.0 W/㎡·K, while that of Low-E insulating glass can be reduced to 1.4–2.0 W/㎡·K. This makes energy efficiency a lot better.

The U-value shows how well glass stops indoor heat from escaping in winter. The SHGC shows how well it blocks summer heat. Together, they tell you how energy-smart the glass is.

Energy Consumption and Comfort

Energy-Saving Effects

- Reduction in HVAC Load with Low-E Glazing

More than half of a building’s energy loss comes from glass in doors and windows. Low-E IGUs cut down heat gain in hot months. They also reduce heat loss in cold months. So, you use heating and cooling systems less all year long.

Indoor Comfort

- Temperature Stability Across Seasons

Low-E glass keeps rooms warm in winter. It keeps them cool in summer. It makes indoor temperatures stay steady, no matter what’s happening outside.

- Reduction of Cold Drafts and Overheating Zones

Low-E glass slows down heat moving through windows, especially near places where people hang out. It stops cold drafts and hot spots. This makes big glass areas way more comfy to be around.

Why Should You Choose Low-E Glass for Architectural Applications?

Energy-Saving Performance

- Winter Insulation: Low-E glass has a lower U-value than float glass. It keeps indoor heat from escaping. This lowers heating bills.

- Summer Heat Reduction: By lowering the SHGC, Low-E glass blocks solar heat. This cuts down on air conditioning costs.

Enhanced Comfort

- Low-E glass keeps indoor temperatures steady. It avoids hot or cold patches.

- Float glass lets in a ton of light. Low-E glass lets you choose how much light comes through. This reduces glare from sunlight. It makes your eyes feel better.

UV Protection

- Low-E coatings block over 70% of ultraviolet rays. This slows down fading of furniture, carpets, and curtains.

Aesthetic Appeal

- Low-E glass gives you options for light passage and reflection. Buildings can look bright and clear or have cool, stylish tones, depending on what the design calls for.

Compliance with Green Building Standards

- The world is all about eco-friendly building now. Low-E glass is often suggested or required in energy rules. It helps projects meet green standards like LEED or other eco-labels.

How Do You Evaluate the Right Low-E Product for Your Project?

Functional Performance

- Insulation and Heat Control: Offline Low-E glass, used in IGUs, gives fantastic insulation. Online Low-E glass, used in single panes, offers decent insulation.

- SHGC Control: Offline Low-E gets a lower SHGC. This makes it better at blocking summer heat. Online Low-E isn’t as good at this.

Durability and Processing Adaptability

- Online Low-E: The coating can handle heat and wear well. It’s great for single-pane use.

- Offline Low-E: The coating is more delicate. It’s usually used in IGUs and needs careful handling.

Cost and Feasibility

- Online Low-E: It’s cheaper. It’s awesome for big, quick projects.

- Offline Low-E: It costs more but performs better. It’s perfect for high-efficiency or fancy projects.

Building Use and Environment

- Single-pane windows or interior dividers with light needs: Online Low-E works fine.

- Large curtain walls, energy-saving buildings: Offline Low-E is the better choice.

Conclusion

By figuring out how float glass and Glasvue Low-E glass differ, builders can make smart picks. These focus on how clear the glass is, how it handles heat, how eco-friendly it is, and how it balances costs with benefits. This helps achieve goals like saving energy, keeping spaces comfy, and lowering long-term costs. Choosing the right glass depends on your project’s needs, like whether you want better insulation or a specific look. Low-E glass, with its energy-saving features and design flexibility, often beats float glass for modern buildings. But float glass still has a place for simpler, less demanding projects.

FAQs

Q1: What makes Low-E glass better than float glass?

A: Low-E glass blocks heat better. It saves energy. Float glass lets in light but doesn’t control heat well.

Q2: Can Low-E glass be used in any climate?

A: Yes, it keeps warmth in during winter. It blocks heat in summer. It’s great for all seasons.

Q3: Is offline Low-E glass worth the higher cost?

A: For projects needing big energy savings, offline Low-E in IGUs gives better insulation. It’s worth the extra cost.