You walk past any new building these days and you can’t miss it – huge walls of glass, giant windows, roof lights that flood rooms with daylight. Behind all that beauty stands laminated glass. It keeps people safe, blocks road noise, stops furniture from fading in the sun, cuts energy bills, and still looks perfectly clear. Architects love it because they can push designs further than ever before. The catch? Pick the wrong thickness and the whole project suffers. Choose the right one and everything works perfectly.

I wrote this guide for the people who actually make decisions: window factories, façade contractors, developers, architects, and builders. My goal is simple – give you straightforward, real-world advice you can trust, no matter where in the world your job is.

Laminated Glass Fundamentals

What exactly is laminated glass?

Take two (or more) sheets of regular glass. Put a tough plastic layer in the middle – usually PVB, SGP or EVA. Heat everything under pressure until the layers become one single unit. Hit it hard and the glass might crack, but the plastic holds every piece exactly where it belongs. No shower of sharp shards, no big hole in the wall.

How modern factories make it

- Loading / Positioning

Two or more panes are laid out exactly to spec (e.g. 5 + 0.76 PVB + 5) and the matching interlayer is prepared.

- Glass cleaning

Full automatic washing line: high-pressure water, soft brushes, pure-water rinse, hot-air dry. Goal: zero dust, fingerprints or water marks – anything left behind kills adhesion.

- Final drying

Any leftover moisture = bubbles or delamination later. Has to be bone dry.

- Assembly (in a clean, climate-controlled room)

The “sandwich” is built: glass + interlayer + glass. Room conditions are non-negotiable: • Temperature 18–25 °C • Humidity 20–30 % • Spotless air (If humidity swings, the interlayer sucks in moisture and you get fog or bubbles – game over.)

- Pre-pressing (initial edge seal)

The sandwich goes through rollers or a flat press to squeeze out air and tack everything together. This step basically decides how clear the final panel will be.

- Autoclave (the real bonding) – the heart of the process

Pre-pressed units go into the autoclave. Typical cycle: • 125–140 °C • ~14 bar pressure • Held long enough for the interlayer to flow and wet out completely. This kills the last microscopic bubbles and locks everything together for good.

- De-kettle & cooling

Out of the autoclave, cool slowly to room temperature, then inspect for bubbles, delam, haze or dirt.

- Final inspection & packing

Check edges are sealed tight, interlayer centred, no defects. Measure thickness, optics, the works. Only perfect panels get packed and shipped.

Which interlayer should you pick?

PVB –the everyday hero. Super clear, blocks 99 % of UV, fair price. Comes in clear, tinted, or special quiet versions.

Acoustic PVB –has much higher damping, so it kills vibration dead. Often a pair of thinner panes with acoustic PVB outperforms a single much thicker monolithic pane for sound insulation, especially mid-to-low frequencies.

Colored or printed PVB – lets you add soft blues, greys, or even patterns without extra panels.

EVA –great adhesion and compatibility, works with all kinds of inserts, perfect for curved glass, decorative work or art pieces.

SGP (SentryGlas®) – the muscle version. Five times stronger and a hundred times stiffer than normal PVB. Designers use it when they want huge panels with almost no frame.

Why architects and owners love laminated glass

Architects love it because it gives them freedom. It stays in one piece on impact, slashes the risk of nasty cuts, and works brilliantly for burglar resistance, fall protection, etc. The damping in the interlayer knocks down noise – a godsend in dense cities. It blocks almost all UV, so carpets and artwork don’t fade. And visually you get crystal clarity plus endless colour and pattern options. Minimalist façades or full-on artistic statements – laminated lets you do it.

Understanding thickness – the part most people get wrong

We write thickness like this: 6 mm glass + 1.52 mm interlayer + 6 mm glass = 13.52 mm total

What happens when you change thickness

Thicker = dramatically safer against impact, flying debris, or attempted break-ins. On big curtain-wall panels it also cuts deflection in high winds so the façade stays flat and the seals last longer. Acoustically, mass + damping = much better performance, especially on low-frequency traffic rumble. Downside: thicker glass gets a slight green edge cast. If absolute colour neutrality matters, spec low-iron.

The downside of going too thick

Every millimetre adds roughly 2.5 kg per square metre. Cranes struggle, shipping costs explode, aluminium frames bend. I’ve seen projects forced to redesign supports just because someone over-specified glass. Balance is everything.

Real-world thickness recommendations

Normal house and office windows

Most jobs run 6.38 mm to 8.76 mm total. Example: 4 + 0.76 PVB + 4 mm or 4 + 1.52 PVB + 4 mm. Plenty strong for daily life, keeps frames slim, meets safety codes almost everywhere.

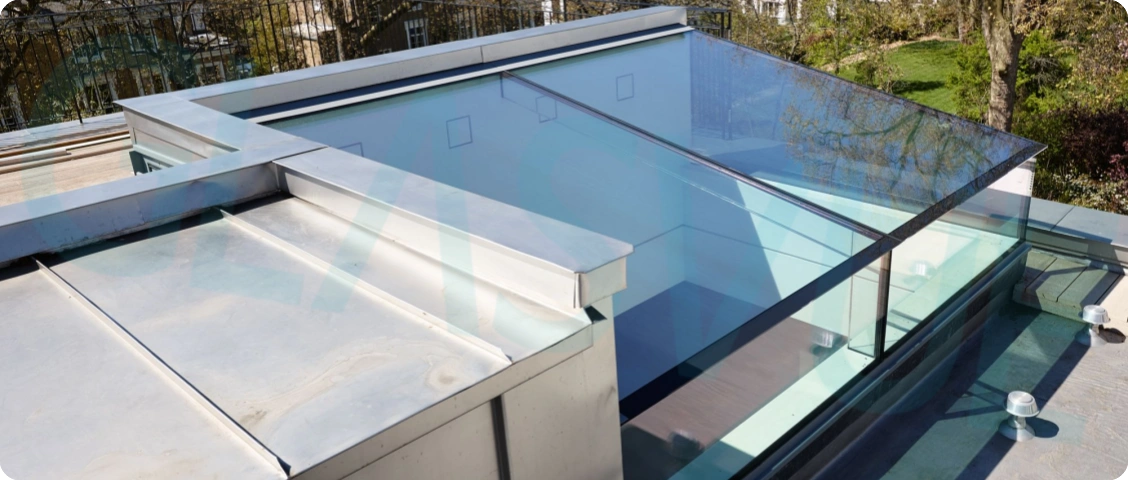

Skylights and anything overhead

Never go below 8.76 mm, usually 10.76 mm or 12.76 mm. At least 1.52 mm interlayer (or SGP). If a tool falls on a roof light, the glass must hold until it’s replaced. Rules are strict for good reason.

Tall building curtain walls and shop fronts

Start at 12 mm total and often go 21–28 mm or more. Common structural picks: 10 + 1.52 SGP + 10 mm = 21.52 mm 12 + 2.28 SGP + 12 mm = 26.28 mm (hurricane zones love this one) Engineers run proper calculations – wind speed, panel size, building sway, local earthquake rules – before locking the spec.

What actually decides the final number?

- Your local building code (never guess this one)

- How big and tall each piece of glass is

- Worst wind your city ever sees

- How quiet the client wants the rooms

- Burglary or blast risk

- The exact look the architect sketched

- Budget and how easy it is to lift on site

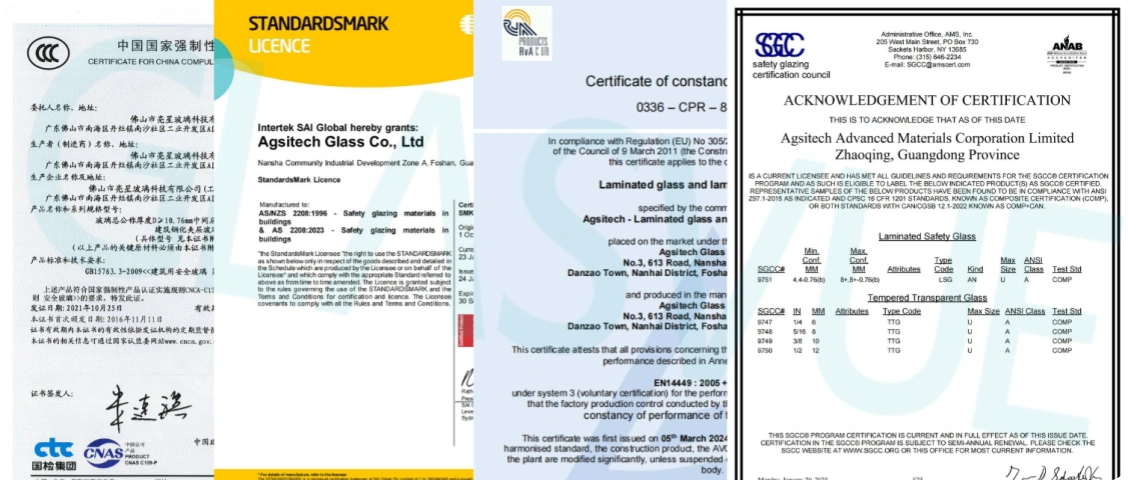

Worldwide certifications Glasvue carries

Our glass is tested and stamped for almost every country: EN 14449 (Europe), AS/NZS 2208 (Australia/NZ), ANSI Z97.1 (USA), GB 15763.2 (China), plus Miami-Dade hurricane and blast certificates when the job asks for them.

Conclusion

Get the thickness right and the building feels safe, calm, and beautiful for decades. Get it wrong and you pay in noise, broken glass, or massive extra steel. Work with someone who understands both the rules and the real site conditions. That’s where Glasvue comes in – we run the numbers, build mock-ups, and ship certified glass anywhere on the planet.

Elevate Your Project with Glasvue’s Expert Services

We do far more than just sell glass

From the first sketch to the final clean-up, our engineers sit with your team. We calculate wind loads, run acoustic models, suggest the lightest possible solution that still passes every test, and follow the glass all the way to site if you need us there.

Talk to a real person today

Drop an email or book a quick call. Most projects get detailed thickness advice, free samples, and firm pricing back the same day or next morning.

FAQs

Q: Does thicker always mean safer?

A: Usually yes for simple impact, but interlayer type often matters more. A 10+1.52 SGP+10 mm panel with SentryGlas can stay in one piece long after a much thicker normal PVB unit would collapse. We see this every time on balconies and glass canopies.

Q: Can laminated glass carry people on floors or stairs?

A: Yes – but only with SGP and normally three layers of glass, like 12+1.52+12+1.52+12 mm. Every square metre gets load-tested in the lab and we add anti-slip frit. Glasvue has supplied certified glass floors for shopping malls, hotels, and private houses across three continents.