In the contemporary architectural discourse, glass has transcended its role as a mere physical barrier against the elements. It has evolved into an “optical medium” that bridges the gap between interior spaces and the natural world. However, architects and developers frequently confront a persistent “Transparency Paradox”: the pursuit of expansive floor-to-ceiling windows for breathtaking views and abundant natural light often leads to an unbearable greenhouse effect during summer months. Conversely, selecting dark or highly reflective tinted glass for heat insulation results in somber, oppressive interiors and can cause significant light pollution to the surrounding urban environment.

As a specialized glass processor with over 20 years of industry expertise, GLASVUE is dedicated to shattering this paradox through the application of nanometric “spectral selectivity.”

The Metric for Breaking the Paradox: Why We Introduce LSG (Light-to-Solar Gain Ratio)

To resolve the conflict between high transparency and low heat gain, we require a performance metric that simultaneously evaluates the balance between these two competing factors. While traditional metrics like U-value (measuring thermal conductance due to temperature differentials) or the Shading Coefficient (SC) (measuring total solar energy blockage) are essential, they often focus on a single dimension of energy efficiency. They fail to intuitively reflect how efficiently a glass product can maintain clarity while selectively blocking heat.

This is precisely why we prioritize LSG (Light-to-Solar Gain Ratio)—the “Gold Standard” for measuring the performance of Spectrally Selective Glazing.

The Formula: LSG = VLT / SHGC

In layman’s terms, LSG measures the “cost” of heat that must be paid for every unit of light allowed into the building.

LSG ≈ 1.0 (Standard Clear Glass): Extremely inefficient. Light and heat enter the space simultaneously and in equal proportions, failing to address the transparency paradox.

LSG ≈ 1.8 (Double-Silver Low-E): The passing grade for modern commercial buildings. This technology begins to perform “subtraction” on the heat while preserving light.

LSG > 2.2 (Triple-Silver Low-E): The flagship configuration from GLASVUE. This level of performance means the glass acts like a precision surgical scalpel, cutting out near-infrared heat while allowing copious amounts of natural light to pass through virtually unimpeded. This is the true realization of “High Transparency” and “High Insulation” coexistence.

The “Golden Formula” for Extreme Performance: A Trinity of System Optimization

Engineering a flagship-grade glass with an LSG exceeding 2.2 is not a matter of simple material stacking. It requires the perfect synergy of three core technological components:

1. The Core Engine: Triple-Silver Low-E Coating

We utilize an off-line vacuum magnetron sputtering process to deposit more than ten layers of nanometric films onto the glass surface. Crucially, this stack includes three distinct, ultra-thin layers of silver. Silver possesses the highest infrared reflectivity of any metal found in nature.

The “Black Tech” Behind It: Triple-silver coatings create an exceptionally “steep” spectral cutoff curve. It allows the visible spectrum (380-780nm) to pass through at high rates but ensures that as soon as the energy enters the near-infrared spectrum (>780nm), the transmittance drops precipitously toward zero.

2. The Perfect Substrate: Ultra-Clear (Low-Iron) Glass

If the coating is a precision instrument, ultra-clear glass is the purest canvas. Standard clear glass contains iron impurities that lend it a greenish tint, which can absorb approximately 10% of incoming light.

GLASVUE Recommendation: We strongly advise pairing Triple-Silver Low-E coatings with ultra-clear substrates. This combination provides an additional 3-5% boost in light transmittance and ensures a Color Rendering Index (CRI) of over 95. This allows the architecture to exhibit a crystal-like purity and ensures that interior colors are perceived exactly as they are in nature.

3. The Systemic Barrier: High-Performance Insulated Glass Unit (IGU) Structures

Argon Gas Filling: Argon is denser than air and has lower thermal conductivity. Filling the IGU cavity with argon significantly reduces the U-value (thermal transmittance) caused by convection.

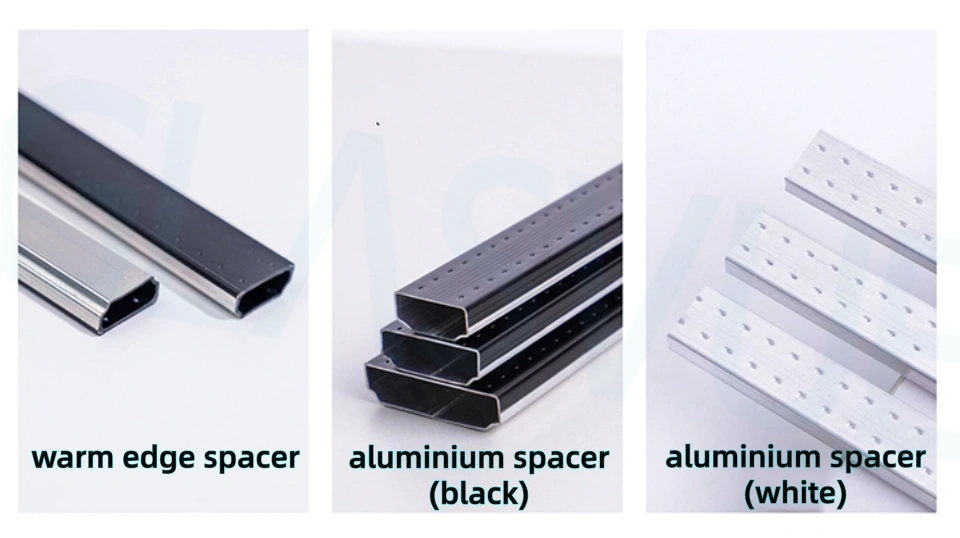

Warm Edge Technology: By discarding traditional aluminum spacers in favor of warm edge spacers with extremely low thermal conductivity, we not only improve overall energy efficiency but also virtually eliminate the risk of condensation at the glass edges during cold seasons.

Factory Secrets: Why Processing Quality Determines Success

Even the most advanced materials can result in a disaster if handled by an unprofessional processing line. The difficulty of processing Triple-Silver Low-E glass is immense due to the delicacy of the film and its thermal properties. GLASVUE ensures that laboratory-grade theoretical parameters are realized in the final building through world-class equipment:

The Art of Tempering

Because Triple-Silver coatings have extremely low emissivity, they reflect heat during the tempering process, which can lead to uneven heating and “roller wave” distortion. We utilize Glaston Forced Convection Tempering Furnaces. By using high-pressure hot air circulation for precise temperature control, we ensure that the glass flatness is as smooth as a mirror, minimizing optical distortion.

The Lifeline of Sealing

Off-line Low-E coatings are highly susceptible to oxidation if exposed to air. GLASVUE operates a Bystronic (Switzerland) fully automated IGU production line. This system features automated film edge deletion and precision sealing technology, allowing us to guarantee a stable service life for the glass system exceeding 10 years.

Application Scenarios: How to Match the Optimal Solution for Your Project?

High-End Residential & Panoramic Windows

We recommend the combination of “Ultra-Clear Substrate + High-Transmittance Triple-Silver Low-E (on Surface #2).” This is currently the most transparent and heat-insulating combination available on the market. It allows you to enjoy outdoor-quality sunlight in your living room while feeling none of the radiant heat waves.

Passive Houses & Extreme Cold Climates

In these scenarios, the design pivots toward minimizing the U-value. We place the Low-E coating on Surface #3, which allows the building to utilize solar heat gain during the winter to assist with heating while effectively “locking” the indoor warmth inside the envelope.

FAQ

Q: Will Triple-Silver glass make the interior look dark?

A: Absolutely not. The human eye is highly sensitive to light transmittance between 60% and 70%. Light filtered through this technology is perceived as softer and more comfortable than direct, unfiltered sunlight, reducing glare while maintaining brightness.

Q: Does this glass affect mobile phone signals?

A: Because of the multiple layers of metallic silver, there is a very slight attenuation of electromagnetic waves. However, in modern buildings with standard window-to-wall ratios, this effect is negligible for daily mobile device usage.

Conclusion

Investing in high-performance glass is more than just a response to environmental regulations; it is a long-term investment in the asset value of the building and the quality of life for its occupants. At GLASVUE, we do more than supply materials. We provide comprehensive data support based on Window 7 thermal modeling to help you precisely realize your architectural vision.

Contact Us: If you are currently planning a high-end curtain wall or a private luxury residential project, please reach out to the GLASVUE technical team. We can provide you with complimentary thermal parameter calculation reports and express delivery of A4-sized samples for your review.

Would you like me to provide a specific technical comparison table between different glass configurations to help you select the right one for your current project?