You’ve probably seen a building external wall or shower door suddenly covered in a web of tiny cracks. This is tempered glass that has ‘shattered’ without falling apart. People often face two key questions in such moments. Does tempered glass ever break? When it does break, is the shattered tempered glass still safe? Tempered glass is made to be 4–5 times stronger than regular glass. It is also built to break in a safe manner. However, it can still fail under certain conditions. Even the “safe” breakage has limits that most people don’t realize. These limits can surprise users in everyday settings like homes or offices. Understanding them helps in making better choices for safety and durability.

What Is Tempered Glass and Why It’s Supposed to Be Safe

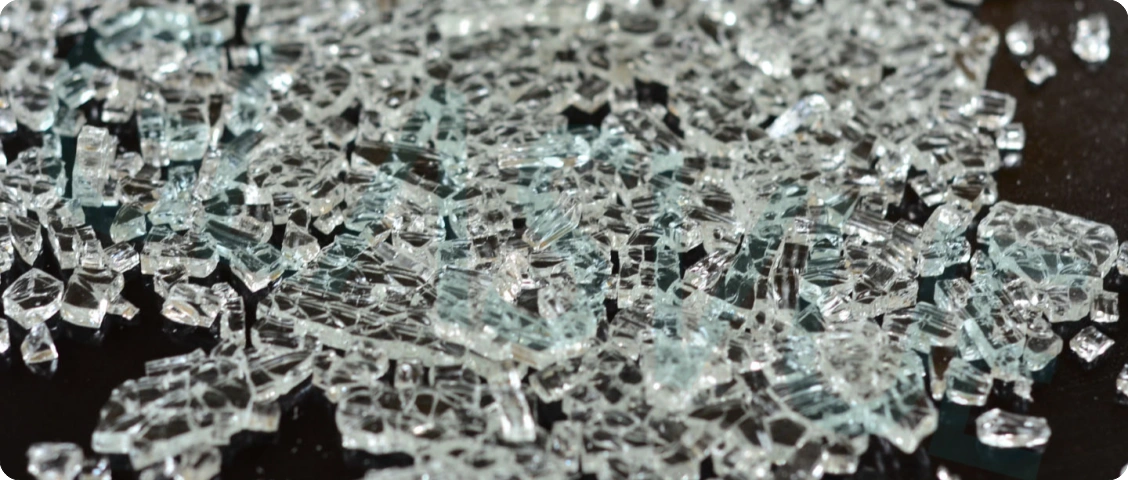

The tempering process involves heating glass to very high temperatures. Then, it cools rapidly on the surfaces. This quick change creates compressive stress on the outer layers. The inside remains under tension. Together, these forces make the glass much tougher overall. The main safety aspect comes into play when the glass breaks. It breaks into small, blunt granules. These are not sharp shards like in regular glass. This feature meets important standards such as ANSI Z97.1 and AS/NZS 2008. Those rules ensure the glass lowers the chance of serious injuries. In places like showers or doors, this design protects people from cuts. Builders rely on it for basic safety needs. Yet, it’s worth noting that no glass is completely unbreakable. The process boosts strength, but real-world factors can test its limits.

Tempered Glass Does Break — Top 5 Real Causes of Spontaneous or Sudden Breakage

One common reason for unexpected breakage is nickel sulfide inclusions. These tiny particles, called NiS, are the biggest cause of spontaneous failures. They form during manufacturing and can expand with heat. This expansion creates internal pressure that leads to cracks without any obvious impact. Another frequent issue is edge damage. This happens during installation or from daily bumps. Even small nicks at the edges weaken the glass over time. They act as starting points for larger breaks. Thermal stress is another key factor. Extreme differences in temperature, like sun on one side and shade on the other, build up strain. The glass can crack to release that tension. Frame binding adds to the problem too. If the frame squeezes the glass too tightly, it applies constant pressure. This ongoing force wears down the material and causes splits. Lastly, impacts that go beyond the glass’s limits often trigger breakage. For example, a fast-moving object like a baseball or tool can hit hard enough to shatter it. Reports from sources like Riot Glass, One Day Glass, and Fab Glass highlight these patterns in actual incidents. They show how these causes appear in homes, cars, and buildings across the country. Knowing them allows for better prevention in design and use.

Best Practices to Prevent Breakage

Proper Edge Protection in Processing & Handling

Protecting the edges during cutting, polishing, and transport is essential. Use soft padding and careful grips to avoid chips or scratches. Workers should handle pieces gently and inspect them regularly. This practice keeps the glass strong and reduces weak points. In factories or on job sites, simple tools like edge guards make a big difference. They prevent minor damage that could lead to full breakage later. By focusing on edges, manufacturers extend the life of tempered glass in real applications.

Avoid Tight Framing / Ensure Proper Clearances

When fitting glass into frames, leave small gaps around the edges. These clearances account for expansion from heat or building shifts. Without them, the glass rubs against the frame and develops stress. Over months or years, this friction causes cracks. Installers should follow guidelines for exact spacing based on size and location. This step ensures the glass stays secure without added pressure. It’s a straightforward way to boost reliability in windows and doors.

Use Heat Soaked Tempered Glass for Facades

For building exteriors like facades, choose heat-soaked tempered glass, known as HST. This type undergoes extra heating after tempering. The process reveals and eliminates NiS inclusions before installation. It cuts the risk of sudden breaks in large panels exposed to sun and weather. Architects often specify HST for high-rises or public structures. The added step provides peace of mind in demanding environments. It aligns with codes for safety in commercial projects.

Manage Thermal Load – Coatings, Frit, Shading

Control heat exposure with low-emissivity coatings or ceramic frit patterns. These treatments reflect sunlight and keep temperatures even. Adding external shading like overhangs helps too. They block direct rays that cause uneven heating. By managing thermal loads, you avoid the stress that leads to cracks. This approach works well in sunny climates or for large glass areas. It combines with other practices for overall protection.

What Actually Happens When Tempered Glass Breaks

When tempered glass breaks, it disintegrates right away into thousands of small cubes. The entire panel fails at once due to the built-in stresses. Before it collapses completely, a distinctive pattern appears. It looks like a spiderweb or crazy paving across the surface. The glass holds in the frame for a short time initially. This happens because the surface compression releases suddenly. It keeps the pieces together briefly before they fall. Visual examples make this clear. Tempered glass breaks into uniform granules. In contrast, annealed glass forms long, pointed shards that scatter dangerously. Laminated glass stays in one piece thanks to its interlayer, but it doesn’t break into safe cubes. These differences show why tempered glass is preferred for safety. Photos from real breaks illustrate the patterns. They help users recognize what to expect and how to respond safely.

Is Shattered Tempered Glass Truly Safe? The Honest Answer

The biggest benefit is a sharp drop in deep cut risks. Unlike annealed glass, the small granules don’t slice deeply into skin. This makes it safer for high-use areas. However, some downsides get less attention. The granules can still cause minor cuts, especially if walked on barefoot in showers. Once shattered, the panel has no strength left. It can collapse unexpectedly and create hazards. In windy conditions or secure spots, the broken area becomes an easy entry point. Real incidents back this up. Shower doors have fallen hours after initial cracking, injuring users below. Allowing break-ins. These cases show that while safer, shattered tempered glass isn’t foolproof. Users should replace broken panels quickly to avoid further issues.

When Standard Tempered Glass Is Not Enough — Introducing Glasvue Security Solutions

Standard tempered glass qualifies as safety glass. But it doesn’t provide security against forced entry or extreme forces. It breaks under impact, leaving openings. For higher protection, advanced options are needed. Glasvue fills this need with specialized products. Our line builds on tempered technology for superior performance. We focus on durability in tough scenarios like storms or threats.

- Hurricane Resistant Glass:This is specifically designed for regions prone to strong winds, typhoons, or hurricanes. Even after the glass cracks, the laminated structure maintains a tight seal to prevent rain, wind, or flying objects from penetrating the building. It fully complies with the strictest building codes in coastal and storm-prone areas and provides reliable protection against high-speed flying debris.A typical high-performance configuration is: 6mm tempered + 1.52mm SGP + 6mm temperedThe ultra-high stiffness and exceptional tear resistance of the SGP ionoplast interlayer ensure that the glass assembly retains structural integrity even after repeated or severe impacts from windborne debris, dramatically outperforming standard PVB laminates in extreme weather conditions. This makes it the preferred choice for coastal residences, high-rise buildings, and critical infrastructure in hurricane zones.

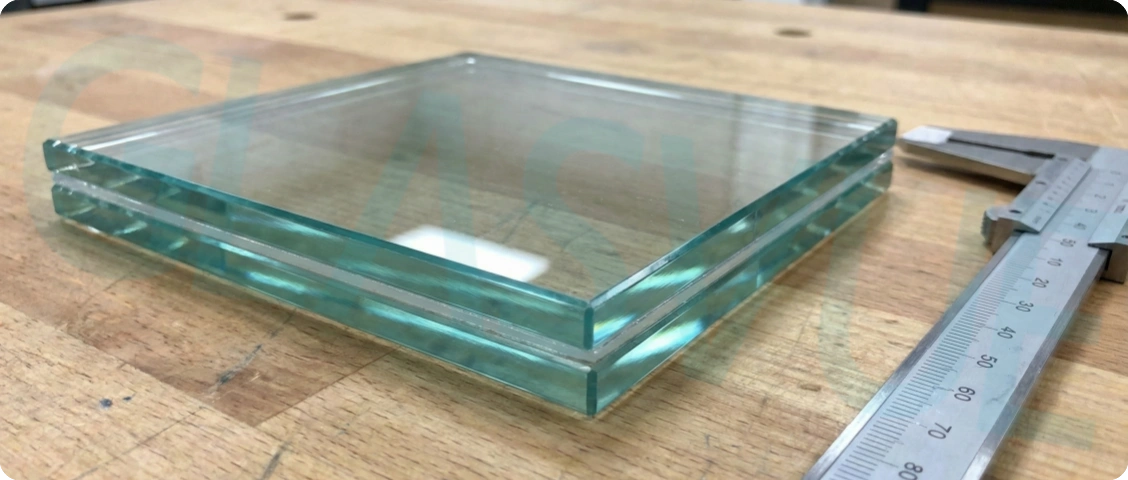

- Bullet Resistant Glass:It uses multiple layers of tempered glass combined with polycarbonate or PVB interlayers. A common Level 1 (Lv1) configuration capable of withstanding 9mm handgun rounds is: 3+1.52pvb+3+1.52pvb+3+1.52pvb+3+1.52pvb+3(total thickness ≈ 22.08 mm).This all-glass laminated structure relies on stacking multiple layers of hard tempered glass bonded with tough PVB films. When a bullet strikes, the first layers shatter the projectile and begin dispersing its kinetic energy, while subsequent layers progressively absorb and stop the remaining force. This setup effectively withstands bullets and explosion forces, making it ideal for high-security sites like banks, embassies, or government offices where real threats are present.

- Shatterproof Glass:This is an enhanced laminated glass that resists hammers, crowbars, and other violent attacks. It meets medium-level forced-entry resistance standard EN 356 P5A with a reliable configuration of 3mm tempered + 1.52mm PVB + 3mm tempered + 1.52mm PVB + 3mm tempered (total thickness 13.52 mm). Even after repeated impacts, the interlayer holds the glass firmly together, preventing penetration and significantly delaying intrusion. It is ideal for retail storefronts, jewelry display cases, high-value merchandise showcases, bank counters, and secure entryways where both visibility and certified anti-smash protection are required.

- High Strength Safety Glass:Our standard tempered glass offers excellent resistance to impacts and thermal cracks. It fits everyday uses in doors, windows, curtain walls, and interior dividers.

At Glasvue, we tailor these solutions to client needs. Our engineering team ensures compliance with global standards. Whether for residential, commercial, or industrial projects, our glass enhances safety without sacrificing design. We draw from years of experience to deliver reliable results.

Elevate Your Project Safety and Performance — Partner with Glasvue

Specifying glass is a key choice. It blends style, energy savings, and user protection. Basic tempered glass covers the essentials. Yet, current building trends call for more toughness. This is true in risky areas with high winds or security concerns. Glasvue offers materials that rise to these challenges. Our products support innovative designs while prioritizing safety.

For Architects and Building Designers

Your ideas must hold up in demanding settings. If a project needs tight security, sits in a storm area, or requires strong impact resistance with clear views, Glasvue has you covered. We supply custom glass that turns plans into code-approved realities. From initial sketches to final installs, our solutions keep clarity and strength intact.

For Window and Facade Manufacturers (OEMs)

Your success hinges on solid, trustworthy components. Adding our certified security glass sets your offerings apart. It follows top international rules and limits legal risks. Join forces with Glasvue to outfit windows, walls, and doors with hurricane-proof, bullet-resistant, or shatterproof options. This upgrade boosts your market edge and client trust.

Take the Next Step

Ready to move beyond ordinary tempered glass?

- Request a Technical ConsultationShare details about your project, such as wind loads, threat levels, or sizes. Our engineers will suggest the best Glasvue option fitted to your setup.

- Download Our Specification SheetFind detailed data on impacts, energy factors, pressure tolerance, and certifications for our full security and strong glass range.

Contact us today to build your next facade, window, or door system for looks, toughness, safety, and confidence.