In today’s world of modern architecture, glass does more than just let light in. It shapes city skylines. It fills rooms with sunlight. And it creates clean lines in new buildings. From tall curtain walls to big storefronts, designers and builders count on glass. They use it to mix beauty with real use. But stop and think about this. Can you really tell tempered glass from non-tempered glass just by looking? At first, they seem the same. Both look clear and smooth. Yet, under that same look hides a big gap in safety and strength. That gap could spell trouble for your project. It might turn a smooth job into a big mess.

Picture this. You pick the wrong glass for a tall building’s front or a busy hall inside. One small mistake could cause breaks during setup. Or failures from heat changes in different weather. Or even dangers that hurt people inside or outside. The results? Late finishes. Checks that fail under tough rules. And extra costs to fix things. These eat up money and hurt your good name. In a time when strong, lasting designs matter most, picking the right glass is key. It’s not just wise. It’s a must. This post looks closely at tempered glass versus non-tempered glass. It shows how companies like Glasvue change building safety. They do it with top-quality, checked products made just for designers and builders around the globe.

Understanding the Fundamentals of Tempered and Non-Tempered Glass

To choose wisely in building design, you need to know the main differences. Tempered glass often fits best for spots where safety counts a lot. Non-tempered glass works for basic parts. But you must be careful in risky places. Let’s go over it step by step.

The Tempering Process: How Glasvue Transforms Glass for Enhanced Building Safety

The real strength of tempered glass comes from its making process. It’s an advanced way to turn plain float glass into a tough material for great buildings. Glasvue leads in China for this. They use top Finnish GLASTON furnaces. These heat raw glass sheets past 600°C (1,112°F). That high heat makes the glass soft. It lets built-up strains ease out. Then comes the key part. Quick blasts of air cool the outside fast. This builds pressure on the surfaces. The inside stays pulled tight. That even pull and push makes tempered glass four to five times tougher than regular glass.

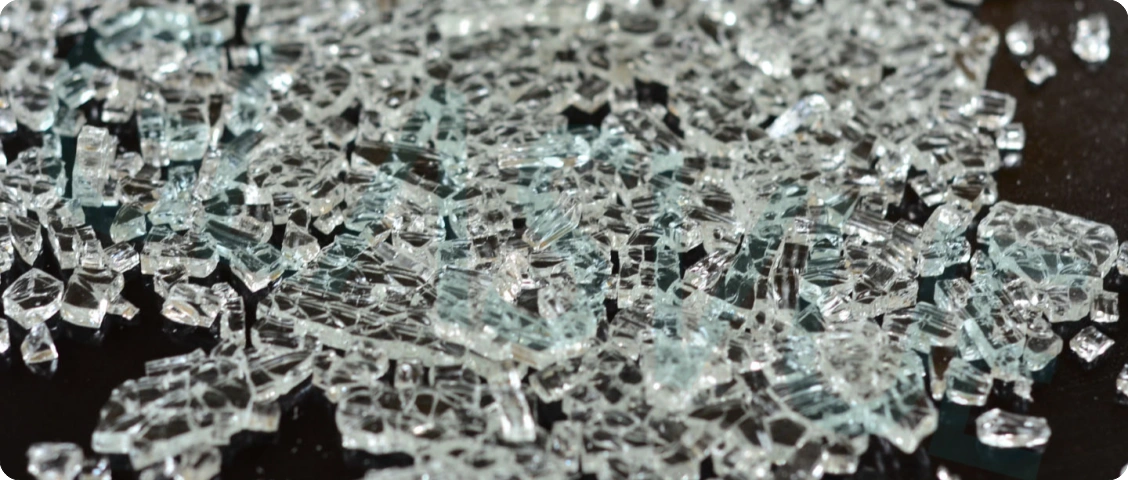

What do you get? Safety you can trust in building skins. If something hits it, tempered glass breaks into tiny, round bits. Not sharp edges. This cuts down on cuts in busy spots like work lobbies or home decks. That break pattern shows it meets world rules. So designers can use it with trust in curtain walls, safety rails, roof lights, and even fronts that stand up to shakes. For green building work, its long life means fewer swaps. This fits with goals like LEED. It helps make building parts last longer in smart designs.

What is Non-Tempered (Annealed) Glass and Its Role in Basic Architectural Elements?

Non-tempered glass, or annealed glass, is the starting point in glass making. It’s made by floating hot glass on tin. This gives flat sheets with no added strains. It’s the basic tool for simple building jobs. People like it for low cost and easy cuts, holes, or edges in making.

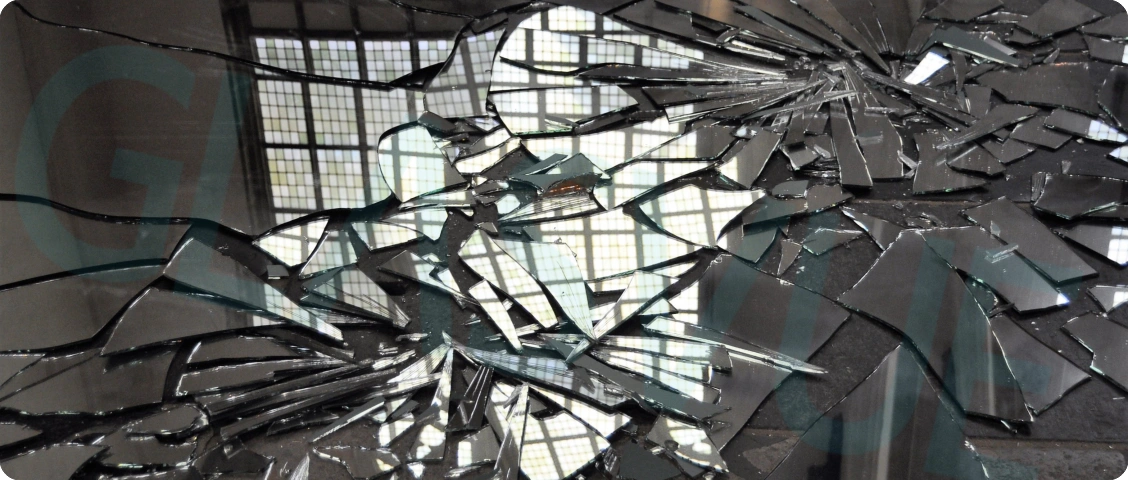

In everyday building uses, annealed glass does well in inside walls, frame windows, or pretty panels. These spots see little bumps from people. But without that pressure layer, it’s weak. It holds only 20-30% of tempered glass’s hit strength. So it can crack from small heat jumps or light taps. And when it breaks, it makes big, sharp pieces. Those can cut bad. That’s no good for open or shop areas. Designers save annealed glass for safe spots. Like art shows or home shelves. But they add safety layers or bonds to cut risks in active building plans.

Performance Comparison at a Glance

To see these differences clear, check this quick side-by-side list. It pulls from world test rules. This chart shows why tempered glass wins in strong building work.

| Performance Indicator | Tempered Glass | Non-Tempered (Annealed) Glass |

| Impact Resistance | High (≥4x stronger) | Low |

| Thermal Shock Tolerance | 200°C | 50°C |

| Fragment Safety | Blunt granules | Sharp, large shards |

| Certifications | EN12150 / AS/NZS2208 / ANSI Z97.1 | No mandatory certification |

| Cost | Moderately higher | Lower |

| Recommended Uses | Doors, windows, curtain walls, railings | Interior decor, low-risk areas |

This list is more than facts. It’s a guide for picking glass that fights wind push in beach towers. Or holds up in city shake zones.

Visual Distinctions: Spotting the Differences with the Naked Eye

Even though they look alike in normal light, tempered and non-tempered glass show clues with easy checks. These ways let designers and workers prove the material’s worth right there. No need for lab gear. They help make sure it passes building looks-over.

Polarization Method: Under Polarized Light, Tempered Glass Shows Stress Patterns

One easy way to check? The light filter test. Take polarized shades or turn your phone screen to block light. Look at the glass from a side angle against bright light. Tempered glass shows bright, wavy color lines. Like a rainbow twist from its pressure parts. Annealed glass stays plain. No marks. This fast look is great for checking glass in wall setups or rail covers. It proves the heat work’s quality before you put it up in open building spots.

Fragmentation Test: Non-Tempered Glass Breaks into Sharp Large Pieces, While Tempered Glass Shatters into Small Granules

For sure proof, try a safe break test on a small edge piece. Hit annealed glass. It splits into pointy, big chunks. You need quick clean-up rules on job sites. Tempered glass bursts into a rain of small, safe pebbles. That’s proof of its built-in safety for top lights or shop fronts. Don’t do this on whole sheets. It wastes. But the test points out why tempered glass is a must in people-focused building. From school halls to hotel spots.

Why Architectural Projects Must Use Tempered Glass?

In the plans for new buildings, tempered glass is not a choice. It’s required for safe spots. World rules like the International Building Code (IBC) and Eurocode 2 say so. They call for safe glass in doors, windows, curtain walls, rails, and top covers. To stop falls that hurt. Break those rules? You face turned-down move-in papers. Or court fights after a wind break.

But rules are just the start. Tempered glass makes building tougher. It stands strong winds in tall city towers. It takes hits from street junk. And it stops random cracks in heat swings on sunny fronts. By cutting risks in moving and setting up, it smooths the job flow. Common headaches in piece-by-piece building. So designers can think big. Like adding smart glass to power-saving skins. Ones that change with who uses the space.

Hidden Risks of Tempered Glass and Solutions

Every material has weak spots. Tempered glass’s power brings small issues. Like random breaks from tiny metal bits inside. Or wave marks from rollers. Glasvue fixes these with smart steps.

The best fix? Heat soak checks (HST). It’s a warm stress bath before ship at 290°C. It sets off bad pieces in safe spots. This drops on-site fails to less than 0.1%.

For clear looks, Glasvue’s GLASTON two-room ovens cut wavy spots. They give flat sheets perfect for simple building styles.

Glasvue’s full HST steps and check layers meet ISO 9001. Every sheet beats or hits EN, AS, ANSI, and ASTM marks. This goes beyond making. It’s a promise for no-risk building safety. From test fronts to big name jobs.

Why Choose Professional Glass Manufacturers from China?

China’s glass world has grown big. It mixes good prices with new tools. Glasvue shows this rise best. With Finland’s top GLASTON auto heat lines, Glasvue makes super-clear, low-metal tempered glass. It lets more light through for sun-filled building work.

Checked to EN 12150, AS/NZS 2208, ANSI Z97.1, and ASTM C1048, Glasvue’s range covers tempered, bonded, filled, and fire-safe types. Made to fit shake areas, storm coasts, or low-energy homes. They ship to over 70 lands. Glasvue helps door/window makers and big build teams. On jobs like green shop towers in the Middle East. Or earth-friendly stays in Southeast Asia. Pick Glasvue for big, trackable lines that match world green aims. Without losing sharp work.

Elevate Your Projects with Glasvue: Services and Next Steps

Expert Consultation, Free Samples, and Tailored Solutions for Architects

Glasvue is more than a seller. We’re your building partner. Our engineer group gives free talks. Ask for no-cost pieces to try in small builds. This makes sure it fits your front systems smooth. From cutting costs in plans to testing bent tempered parts, Glasvue’s custom fixes turn big ideas into strong facts.

Contact Glasvue Today to Discover Tempered Glass Excellence

Set to guard your next job? Hit our site for a free price. Let’s team up on glass that beats rules. It lifts building work.

Conclusion — Safety Isn’t an Option, It’s a Standard

In the big weave of building plans, each glass bit adds to strong setup and people care. Put money in tempered glass like you buy guard for your job’s future. It’s a wall against hidden dangers. A base for bright looks. And proof of smart choices in a wild world. Team with checked sellers like Glasvue. You don’t just follow rules. You lead with top work. It builds trust and long good. Keep in mind. In building, safety is not extra. It’s the base. Pick smart. Build to last.

FAQ

Q: How can I tell if the glass in my current building project is tempered without professional tools?

A: Use the polarization test: View the glass through polarized lenses (like sunglasses) against a light source. Tempered glass will show colorful stress patterns, while annealed glass appears uniform. For confirmation, consult your supplier’s certification docs or perform a edge-fracture sample test.

Q: What architectural applications benefit most from Glasvue’s tempered glass solutions?

A: Glasvue’s tempered glass excels in high-impact areas like curtain walls, balustrades, skylights, and storefronts in commercial and residential buildings. It’s ideal for seismic, hurricane, or urban environments, enhancing wind resistance and safety while supporting sustainable designs with low-iron options.

Q: Does Glasvue offer support for customizing glass to meet specific building codes?

A: Absolutely. Our expert consultations tailor tempered, laminated, or insulated glass to comply with IBC, Eurocode, or local regs. We provide detailed specs, free samples, and Heat Soak Testing to ensure your project passes inspections seamlessly, from high-rises to public venues.