In modern business building design, glass has grown way past its old jobs of letting in natural light and creating barriers, turning into a tool that lets builders show feelings and ideas. In this time ruled by the “visual economy,” color stands out as the key part that sets plain buildings apart from famous ones. From the shiny desert gold of Dubai’s Burj Khalifa to the simple gray of London’s Shard, every building people remember uses its own color choices to tell its special tale.

Still, making design ideas come true in real life brings big problems. For makers of windows and doors, experts in curtain walls, and people who build projects, the main issue comes from finding a steady helper who can copy the planned colors exactly while keeping tight watch on color changes during big factory runs.

This is exactly what Glasvue aims to do. As a maker of building glass with full control over deep processing in every step of the supply chain, we do not just make glass but help create art with light and dark. From careful heat-reflective coatings to colors that resist fading through high heat in ceramic frits, and from see-through but lively colored laminates, Glasvue gives full color fixes, helping builders around the world turn their plans into lasting city sights.

Key Elements of Commercial Curtain Wall Glass

Structural Safety and Wind Load Resistance

Acting as the building’s first shield against storms and harsh weather, the strength of curtain wall glass builds the base for all design thoughts. Every piece needs tough checks on loads based on the building’s height and exact wind pressure areas to make sure it works without fail. In tech terms, we use tempered or heat-strengthened glass, which gives power three to five times stronger than normal annealed glass, handling strong winds up high well. To make safety even better, we add SGP or PVB laminated layers inside, so if it breaks, the bits stick tight to the layer, stopping falls from high up and giving the best guard for people on the ground. Plus, heat soak testing (HST) counts as a must-do step for tempered glass in tall buildings, cutting down chances of sudden breaks and adding extra safety.

Superior Energy Performance

Glass acts as the main spot for heat swap in a building’s outer layer, affecting costs to run it over time in a direct way. Great commercial curtain walls need to find the right mix between letting light through and keeping heat in, reaching low heat transfer rates (U-values) to hold room warmth while keeping exact shading rates (SC) to stop sun heat. Glasvue gets this done with strong Low-E coatings or heat-reflective methods, mixed with insulating glass units (IGUs) filled with argon, building top energy blocks. This cuts down a lot on power used for cooling and heating, letting projects meet LEED, BREEAM, or local green rules easily, bringing good money savings and help for the earth.

Visual Flatness

Famous buildings call for curtain walls that look smooth like mirrors, making clear reflections without twists—a basic need for how they look. Usual tempering steps often bring in waves or spots from rollers, hurting the even look of the front. To get better sight quality, we focus on heat-strengthened ways or very exact tempering tools. When safety rules allow, heat-strengthened glass gives smoother surfaces than full tempered glass, cutting down sight twists and truly bringing the builder’s idea of pure looks to life, so the building shows its nicest shape as light and shadows change.

Color Consistency and Durability

Business projects often use tens of thousands of square meters of glass sent out over long making times, so controlling color shifts from one batch to another marks the biggest hurdle. Whether it’s glass coated with metal tones or glass with art-like patterns from ceramic frit, Glasvue uses the newest tools (like Glaston tempering furnaces) and strict Delta E checks for color differences to make sure every piece has even and steady colors. We promise the same color truth from first shipments to later fixes, standing up to time and sun for colors that stay bright over years.

Three Ways to Color Your Facade

To meet the wide range of look needs in today’s building styles, Glasvue offers three main ways to add color. From metal coatings that give a cool tech feel, to lasting ceramic frits that mix art with real use, to full-of-life PVB laminates that release color power, our full fixes turn every color idea from builders into real parts of the front of buildings.

A. Heat-Reflective IGU

Aesthetic Style: Gives a fresh, plain front with a tech shine, building a high-end, private work space feel.

In-Depth Analysis: For tall buildings and city center spots chasing city newness, Glasvue uses advanced coating tech to put thick metal oxide layers on the glass outside. This heat-reflective glass brings great one-way mirror looks in day light: from outside, it copies the moving sky, clouds, and nearby things like a shiny surface while hiding inside views for private space; from inside, it keeps soft, clear sight.

We have choices in basic shades like silver-gray, blue-gray, champagne gold, and ocean blue, fitting well for top office spots and tech areas.

Recommended Glasvue Configuration:

Outer Pane: 6mm heat-reflective coated glass (tempered + HST) — the main color part, copying sky and surroundings.

Spacer: 12A (Air/Argon) — heat block.

Inner Pane: 6mm clear glass (tempered + HST).

B. Ceramic Frit IGU

Aesthetic Style: Blends art and real work well, making front patterns with flow through full and empty spots.

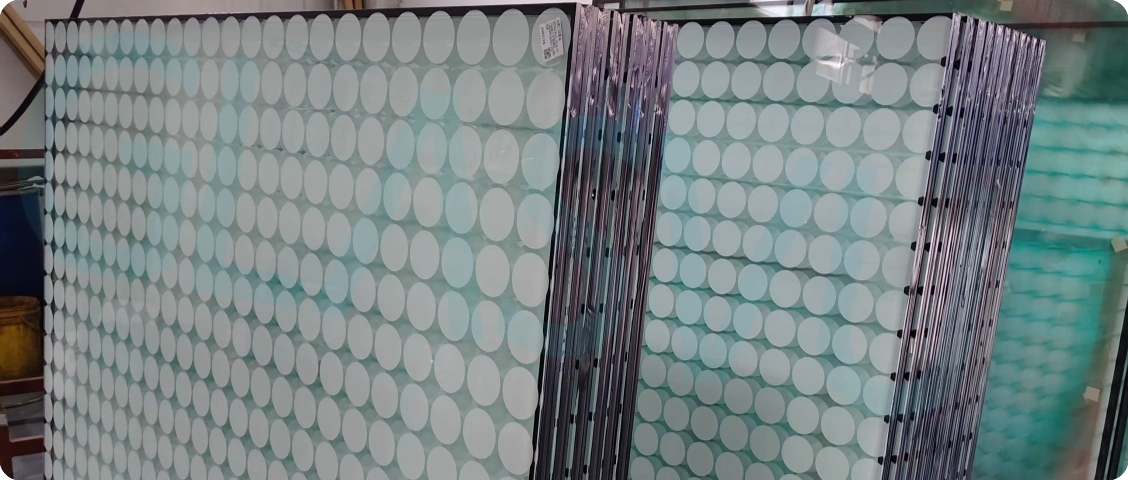

In-Depth Analysis: For buildings that need strong patterns or lasting hide parts, ceramic frit glass works best. Glasvue picks very weather-tough inorganic frits, printed exactly with screens and stuck forever to the glass outside. This color way does not fade, fights off acids and bases, and lasts as long as the building. We give full frit cover for spandrel spots, hiding concrete beams, posts, and inside systems while keeping the front look the same; we can change dot, line, or fade patterns to control light coming in just right while adding light touch and flow to the building’s skin.

Recommended Glasvue Configuration:

Outer Pane: 6mm high-temperature ceramic frit glass (tempered + HST) — giving strong decor and shade.

Spacer: 12A.

Inner Pane: 6mm clear glass (tempered + HST).

C. Vibrant Laminated IGU

Aesthetic Style: Lets out color life while keeping glass see-through, giving strong sight hits.

In-Depth Analysis: When normal coatings do not meet builders’ needs for strong colors like bright red, lively orange, or deep green, top colored PVB layers inside give the best fix. Unlike outside treatments, colored PVB sits safe between glass layers, keeping clear glass shine with a wide range of colors.

Technical Highlight (Heat-Strengthened Process): To make the best smooth sight, Glasvue suggests heat-strengthened glass for the laminated outer part. Next to full tempered glass, it shows less bend from rollers, stopping twists in color layers. Heat-strengthened laminated glass also gives better strength after breaks, making building safety stronger.

Recommended Glasvue Configuration:

Outer Pane: 4mm clear (heat-strengthened) + 0.38mm colored PVB + 4mm clear (heat-strengthened).

Spacer: 12A.

Inner Pane: 6mm clear glass (tempered + HST).

Case Study: Avani Hotel, Melbourne, Australia

Set in the heart of Melbourne, the Avani Hotel shows a fresh business hotel build that goes after simple looks while setting hard rules on glass clearness and smooth setup after putting it in.

To handle these real look and work needs, Glasvue gave a custom fix that fit just right.

Glasvue Solution Configuration: 6mm Clear Single Low-E Tempered HST + 12A (Black Spacer) + 4mm Clear HS + 1.14mm Clear PVB + 4mm Clear HS

In-Depth Configuration Analysis: Why This is the Optimal Choice

- Invisible Aesthetics:Black warm-edge spacers show close care for small parts. To match the building’s dark frame system, we chose black warm-edge spacers, getting rid of sight issues from old silver aluminum spacers and making edge hides smooth in the frame for one full front blend.

- Balanced Vision and Safety:The inner pane’s 4mm + 4mm heat-strengthened laminated build (HS + PVB + HS) shows Glasvue’s skill.

- Ultimate Flatness:From outside looks, the curtain wall seems like a perfect smooth mirror, without any twisty views, clearly copying Melbourne’s city lines and lifting the building’s height and nice style.

- Structural Safety:The 1.14mm PVB layer not only cuts sound but also builds a strong safety wall. In worst break cases, heat-strengthened glass’s big crack way mixed with tough PVB keeps the unit standing, giving max safety for guests.

- Energy Efficiency and Compliance:The outer pane’s single-silver Low-E tempered glass with HST gets rid of sudden break risks up high while giving good energy work. Glasvue’s items fully meet hard Australian rules AS/NZS 2208 & 4666, winning big thanks from Australian buyers for on-time sends and better quality.

Conclusion & Partnership

In the end, picking curtain wall glass for business buildings means finding the right mix between building strength and design looks. From heat-strengthened steps that stop sight twists to heat-reflective, ceramic frit, and colored PVB fixes that bring special front effects, Glasvue works hard to give full fixes from picking raw glass to sending out deep-processed items.

Reasons to Choose Glasvue: Dual Assurance of Capacity and Compliance

- Industrial-Scale Capacity:Our new making plant covers over 20,000 square meters, with top tools from Finland like Glaston tempering furnaces. This makes sure smooth standards like those around the world for tempered and heat-strengthened glass, with a yearly make of 1.2 million square meters—handling big buys from window and door makers or quick project needs with steady, long sends.

- Global Compliance Passport:Our items stick to world rules, with papers like Australia’s SAI Global (AS/NZS 2208/4666), USA’s SGCC (ANSI Z97.1), and Europe’s CE (EN12150). This lets easy fit with local build codes in works from Sydney to New York or London, cutting out check risks.

Connecting the Global Supply Chain

If you look for a curtain wall helper who can watch color differences closely and give steady long supply, or if you own a project chasing special color fixes, Glasvue stands as your sure partner.

Reach out to us right away for pro price quotes and tech help made for your build.