In current building designs, windows often earn the label of “thermal holes” in a structure, accounting for as much as 70% of the heat that enters or escapes. If you are putting together a high-end home complex or a prominent business tower, selecting the proper glazing becomes the key choice for energy efficiency, sound control, and lasting strength.

Yet, the marketplace offers a bewildering array of costs. You may notice two glass pieces that appear the same at first look, but one demands double the price of the other. This overview seeks to reveal the “price versus performance” discussion, guiding you through the fine details to spot the top payback for your effort on the job.

The Glass Substrate: The Foundation of Clarity and Energy Control

The expense of an IGU begins with the basic panes of glass employed.

Standard Clear vs. Low-Iron (Ultra-Clear) Glass

Regular float glass shows a faint green hue from its iron makeup. For upscale tasks, specialists suggest Low-Iron glass (like Taiwan Glass or Xinyi Glass). It eliminates that “bottle-green” border, delivering better color balance and strong light passage. Though it adds to the cost, the visual gain—particularly in heavy layered or triple-glazed setups—is clear and worth it.

The Evolution of Low-E Coatings

Every type of “Energy Saving” glass does not match in quality. Low-Emissivity (Low-E) coatings form very fine metal films (typically silver) that send heat away.

Single Silver: The basic option that fits simple power standards.

Double & Triple Silver: These excel at “cool light” delivery. They stop much more infrared warmth while permitting the most visible brightness. A Triple Silver Low-E unit reaches a quite low Solar Heat Gain Coefficient (SHGC) without leaving the inside dim.

The Edge Seal: The “Heart” that Determines Longevity

If glass serves as the frame, the seal functions as the core. The top cause of IGU breakdown is “fogging”—moisture buildup inside from a failed seal.

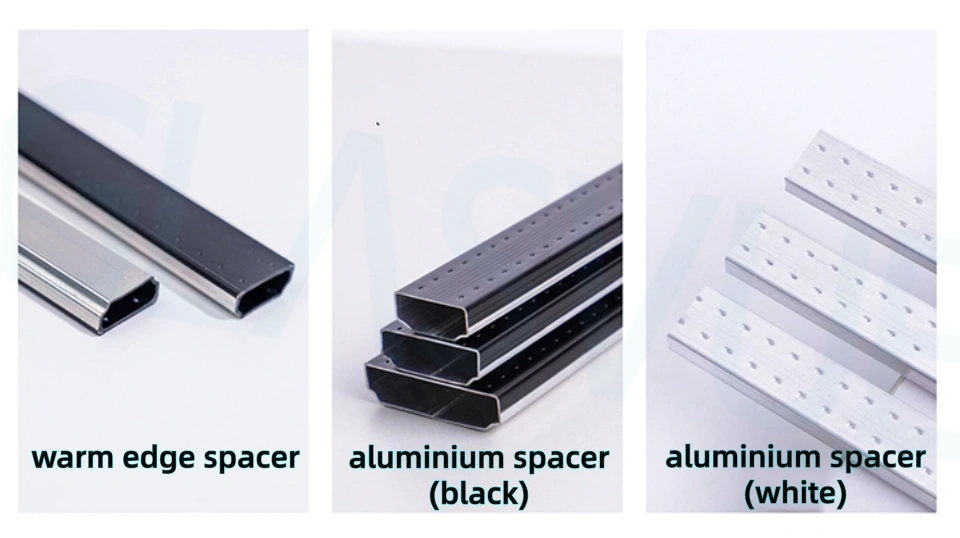

Aluminum vs. Warm Edge Spacers

Common setups commonly include Aluminum spacers, a sturdy and field-tested pick for various structure kinds. Although aluminum conducts heat and might form a “thermal bridge” along the glass edge—which could cause outer moisture in sharp temperature shifts—it continues as a routine and useful element for most uses. For efforts aiming at better warmth retention and stronger power marks, Warm Edge Spacers (formed from blended materials or stainless steel) offer a solid substitute by reducing edge warmth escape. This maintains the glass border at a higher temperature and boosts inside ease further. At GLASVUE, we supply both aluminum and warm edge selections, letting you choose the setup that matches your task’s warmth needs and spending limit best.

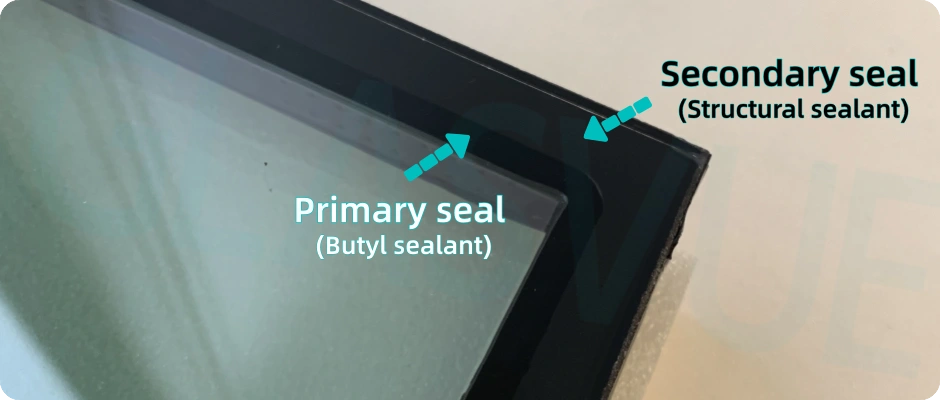

The Power of Dual Sealing

At GLASVUE, we always uphold the sealing structure without shortcuts.

Primary Seal (Butyl): This acts as the dampness block that bars water and holds argon gas inside.

Secondary Seal (Structural Silicone): This supplies the physical power to bind the unit amid wind forces and heat changes. Inexpensive “single-seal” units typically quit after 3–5 years, while a well-built dual-seal unit from a premium range endures beyond 20 years.

Cavity Filling: Performance vs. Project Requirements

Though dry air stays the most common and budget-friendly fill for ordinary Insulated Glass Units, Argon gas has grown as a favored boost for tasks facing stricter power-cut demands. Argon packs denser than air, aiding to ease inner air movement and lessen heat shift across the unit.

Combined with a 12mm to 16mm space and a Low-E layer, choosing Argon fill can improve the U-value (heat escape measure) by another 15–20%. At GLASVUE, we deliver both dry air and Argon gas fill choices according to your exact task demands and warmth targets. No matter the pick, our skilled production accuracy guarantees the space stays well-closed and keeps its form through the structure’s full life.

Advanced Processing: Safety and Functionality

Strong-performing IGUs need targeted handling to surpass regular float glass limits.

Toughened (Tempered) Glass: The Safety Standard

To match today’s safety guidelines and handle outside pressures, fine IGUs generally use Toughened Glass. This method renders the glass 4 to 5 times tougher than usual float glass and makes sure that, should it break unexpectedly, it crumbles into tiny, rounded bits instead of pointed fragments. Past core safety, toughening improves the unit’s heat steadiness and acts as the required base for added safety steps like the Heat Soak Test.

The Heat Soak Test (HST)

Every tempered glass holds a tiny chance of sudden break from Nickel Sulfide (NiS) specks. For tall business structures or ceiling glass, Heat Soak Testing proves vital. It serves as a “fast aging” step done post-toughening; the glass enters a dedicated furnace to spark any likely NiS issues at the plant, preventing breaks in place after fitting.

Specialty Coatings

Self-Cleaning/Easy-Clean: A plastic film that prompts water to flow off in sheets, carrying soil along—key for out-of-reach business fronts.

Bird-Friendly Design: Applying clay dot designs or UV films to avoid bird strikes, an increasing need in Western eco-building rules.

Why GLASVUE: Redefining Manufacturing Standards

At GLASVUE, we go past mere glass assembly; we build effectiveness. Our dedication to excellence rests on a top-tier production setup:

Premium Material Sourcing: We draw solely from the sector’s “Big Three” glass bases—Taiwan Glass, Xinyi Glass, and Jinjing. This secures a starting material with minimal flaw counts and top build firmness.

Glaston Automated Lines: Exactness allows no debate. Our outlay in Finnish GLASTON automated IGU lines secures flawless positioning, even sealant spread, and a dirt-free setting.

Seamless Integration: Our automated spacer bending technology removes the four edge links in low-cost units—the usual leak spots. By forming a one-piece border, we heighten gas holding and water resistance in each unit.

Industrial Scale: With an annual capacity of 300,000 square meters, we possess the reach to manage vast business wall systems while upholding the craftsman care needed for tailored upscale home efforts.

Conclusion: Partner with Experts in Performance

Glazing stands as more than a construction item; it represents a lasting outlay in ease, eco-friendliness, and design outlook. Opting for GLASVUE selects over 20 years of know-how and the assurance tied to a broad array of international approvals, including ISO 9001 (Quality Management), AS/NZS 2208 & 4666 (Australia/New Zealand), ANSI Z97.1 & SGCC (USA Safety), ASTM E2190 (USA IGU Standard), CE/EN 14449 (Europe), and CCC (China).

Ready to Optimize Your Next Project?

Avoid basic “standard” when “high-performance” lies within reach.

Get a Technical Consultation: Allow our specialists to pair the ideal layer with your local weather area.

Receive a Custom Quote: We supply output-to-cost balances that yield the finest worth in the worldwide trade.

Explore Our Portfolio: View how GLASVUE has aided builders globally in achieving their boldest concepts.

FAQs

1.What is the main difference between Single, Double, and Triple Silver Low-E coatings?

The “silver” denotes the count of bounce-back films in the layer. Greater silver counts yield improved “spectral selectivity”—the ability to block infrared heat yet permit ample visible brightness. Triple Silver Low-E delivers the peak energy efficiency, suiting vast fronts where you seek to enlarge sights minus the hothouse outcome.

2.Does using Low-Iron glass provide any functional benefits beyond aesthetics?

Past its sharp look and the loss of the green shade, Low-Iron glass truly grants a touch higher Visible Light Transmission (VLT) (VLT). This aids notably in expansive-layout structures or home zones where sun glow matters most. It ranks as the field norm for posh tasks where sight clarity rules.

3.Why is Heat Soak Testing (HST) considered a “must-have” for high-rise projects?

Tempered glass bears a small yet actual chance of unprompted break from Nickel Sulfide specks. In a tall structure, replacing a single broken pane at 30 levels up proves hugely pricey and setup-hard. HST forms a type of “coverage”—it spots and snaps risky sheets at the worksite, assuring your fitted front stays secure and whole for years.