In contemporary architectural design, the extensive use of large-scale glazing has bestowed spaces with a transparent aesthetic value. However, it also represents the weakest link in a building’s energy performance. As global decarbonization goals advance and green building standards become ubiquitous, the industry’s focus has shifted from mere daylighting to the pursuit of high-performance thermal management. High energy consumption, physical discomfort, and UV damage caused by traditional glazing solutions have become significant pain points for commercial architecture. The key to resolving this paradox lies in the application of Low-E technology. This article provides a deep dive into the physical mysteries of Low-E glass and highlights how Glasvue, through world-class deep-processing craftsmanship, provides the ultimate holistic solution that balances aesthetics with energy efficiency.

Deconstructing the Spectrum: The Physical Principles of Low-E

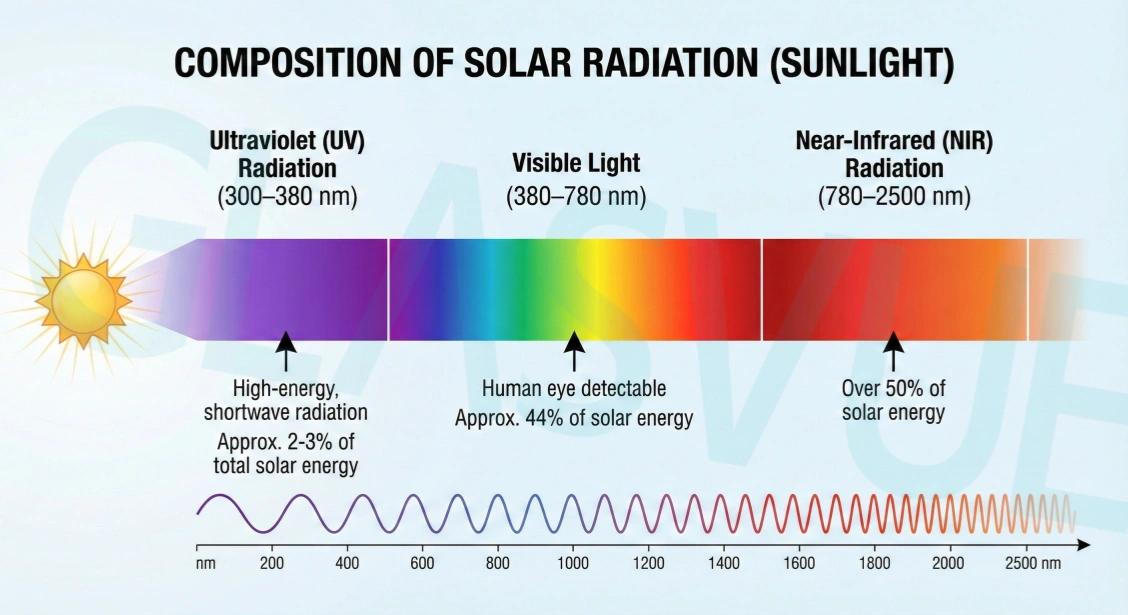

To understand how Low-E glass achieves energy savings across complex climatic environments, one must first recognize the physical composition of solar radiation. The essence of Low-E (Low-Emissivity) lies in its “spectral selectivity”—the ability to specifically filter and manage energy across different wavelengths.

Solar Spectral Energy Distribution: The Source of Heat and Light

Solar radiation energy is primarily distributed within the wavelength range of 0.3μm to 2.5μm. For precise thermal management, we must categorize this into three core dimensions:

Ultraviolet (UV) (approx. 3% of total energy): Located in the short-wave band of 280-380nm. Although its energy proportion is low, it possesses strong chemical destructiveness. It is the primary cause of fading and aging in indoor artworks, carpets, and high-end furniture. Superior deep-processing must consider how to maximize the blockage of this band through specific coating combinations.

Visible Light (approx. 44% of total energy): Located in the 380-780nm band. This is the sole source of human visual perception of architectural transparency. A high-performance Low-E system must maintain ideal transmittance in this band to ensure indoor lighting quality and reduce artificial lighting energy consumption.

Infrared (IR) (approx. 53% of total energy): Specifically, near-infrared radiation between 780-2500nm. This part of the radiation does not contribute to brightness but is the primary carrier of solar heat. In summer, it is the “invisible hand” that causes indoor air conditioning loads to surge, and it is the primary target for reflection and shielding by Low-E coatings.

The Structure of Low-E Coatings and Energy Management Logic

Low-E, or Low-Emissivity, is not a single coating in physical terms but a composite film system consisting of multiple layers of nanoscale materials.

Anatomical Composition of the Coating and Its Role

A typical high-performance Low-E film system is generally composed of the following three types of functional layers stacked alternately:

Functional Layer (Silver, Ag): The heart of Low-E. Silver possesses extremely low emissivity and exceptionally high thermal reflectivity. It is responsible for blocking far-infrared thermal radiation and is the core physical layer for achieving energy savings.

Dielectric Layers (Metal Oxides, e.g., ZnO or SnO2): Located on both sides of the silver layer. These not only protect the silver from wear but also use interference principles to reduce reflection, increase glass transparency, and adjust the visual color of the glass.

Barrier Layer (Protective Layer, e.g., NiCr): An extremely thin sacrificial layer used to protect the silver layer from oxidation during production or tempering, ensuring the chemical stability of the functional layer.

The Physical Logic of “Warm in Winter and Cool in Summer”

Through the collaborative operation of these film structures, Low-E glass achieves efficient management of long-wave thermal radiation:

Summer (Shielding Outdoor Heat): By maintaining extremely low absorption and high reflectivity, the glass blocks far-infrared thermal radiation (heat waves) generated by the sun. While ordinary glass has an emissivity as high as 0.84, a coated Low-E surface can drop this value to 0.03. This film system acts as an “optical mirror” for heat, significantly reducing solar heat gain.

Winter (Locking in Indoor Heat): Heat generated by indoor heating systems and objects also exists as long-wave infrared radiation. The Low-E coating acts like a “thermal blanket,” reflecting this heat energy back into the room and preventing it from escaping to the frigid outdoors. This “light-permeable, heat-resistant” characteristic provides buildings with excellent passive energy-saving effects.

Key Performance Indicators for Commercial Building Selection

In engineering selection, whether a piece of glass deserves the title of “high performance” depends on the balance of three core parameters:

U-Value (Thermal Transmittance) The U-value measures the rate of heat transfer through the glass due to temperature differences. A lower value indicates superior thermal insulation performance.

SHGC (Solar Heat Gain Coefficient) SHGC defines the fraction of incident solar radiation that enters a building through the glass.

Selection Philosophy: Lower is not always better. Frigid regions may require a higher SHGC to gain “passive solar heat,” while hot regions require an extremely low SHGC to reduce air conditioning investment and operating costs.

VLT and LSG: The Art of Balancing Light and Heat Visible Light Transmittance (VLT) determines the sense of transparency. LSG (Light-to-Solar Gain Ratio = VLT / SHGC) is the ultimate indicator of Low-E technical prowess. Top-tier Triple Silver Low-E glass can achieve an LSG > 2.0 while still allowing ample, natural visible light to flood the interior.

The Battle of Manufacturing Processes: Offline vs. Online Low-E

The final thermal performance and visual quality of Low-E glass depend heavily on how the coating is attached during the raw sheet production phase. As deep-processing experts, Glasvue insists on selecting high-standard Low-E raw sheets globally, scientifically adapting between “Online” and “Offline” technical paths based on the project’s energy requirements and architectural form.

Online Coating (Hard Coat): Physical Fusion at High Temperatures

Online Low-E is produced on a float glass line while the glass is still at an extremely high temperature, using Chemical Vapor Deposition (CVD) or pyrolytic deposition to spray functional materials onto the surface.

Physical Characteristics: Because the coating is “embedded” into the surface during formation, it integrates with the glass substrate, offering high mechanical hardness and chemical stability.

Core Advantages: Its greatest feature is “weatherability.” Online Low-E can be stored long-term without special protection and can be processed like ordinary glass—tempered, heat-bent, or even used as a single pane.

Limitations: Restricted by the production environment, the coating composition is relatively simple, and the emissivity is typically around 0.15. While better than ordinary glass, it struggles to meet the extreme energy-saving demands of top-tier commercial buildings.

Offline Coating (Soft Coat): Nano-Art in a Vacuum

Offline Low-E is a sophisticated system created by layering silver and dielectric materials onto finished glass substrates using Magnetron Sputter Vacuum Deposition (MSVD).

Physical Characteristics: The film structure is incredibly precise and complex, allowing for customized Single Silver, Double Silver, or even Triple Silver structures, with emissivity dropping below 0.03.

Performance Peak: Offline coating is currently the “ceiling” of energy-saving technology for residential and commercial glass. It achieves the best Light-to-Solar Gain (LSG) ratio, maintaining high daylighting while blocking the vast majority of solar thermal radiation.

Glasvue’s Processing Logic: Because the silver layer in offline coatings is susceptible to oxidation and damage when exposed to air, it is often referred to as a “fragile” semi-finished product. Glasvue’s core value lies here: we are equipped with fully automated pretreatment and edge-deletion systems, ensuring that raw sheets are cut, edge-deleted, cleaned, and tempered/insulated within the “golden window” after unboxing, perfectly “sealing” the peak thermal performance of Offline Low-E within the IGU (Insulated Glass Unit) system.

Excellence in Processing: How Glasvue Craftsmanship Defines Finished Energy Efficiency

High-performance Low-E raw sheets only represent a theoretical performance ceiling. The quality of deep processing determines whether these nanoscale coatings can stably perform over decades of a building’s lifecycle. In Glasvue’s production philosophy, processing is not a simple change of form, but an ultimate guardianship of optical precision and thermal stability.

Precision Pretreatment: The First Line of Defense for Performance

Offline Low-E coatings are extremely sensitive to the environment. Any minor oxidation or scratch can cause the entire pane’s performance to collapse.

Glasvue’s Solution: We utilize Italian Bottero fully automated high-precision cutting and pretreatment systems. These machines integrate advanced Automatic Edge Deletion functions, precisely removing the coating within a 10-12mm range of the glass edge during cutting.

Physical Value: This step is critical for the lifespan of an IGU. Once the edge coating is removed, the sealant (polyisobutylene/butyl) can bond directly with the glass substrate, forming an absolute airtight barrier. This eliminates chronic gas leakage and energy-saving failure caused by coating oxidation at the seal.

Forced Convection Tempering: Reshaping Ultimate Optical Flatness

Tempering is the most challenging stage of Low-E processing. Because Low-E coatings reflect heat, traditional radiation heating furnaces cause extreme temperature imbalances between the top and bottom surfaces of the glass, leading to severe roller waves and optical distortion.

Glasvue’s Solution: We rely on Finnish Glaston FC and Chinese North Glass top-tier forced convection tempering furnaces.

Result Orientation: By using high-pressure airflow for “forced convection heating” controlled thousands of times per second, we effectively counteract the thermal reflection barrier of the coating. This ensures that large-scale (and even oversized) Low-E glass maintains ultimate Optical Flatness and zero-distortion visual quality, allowing the building facade to present a mirror-like transparency.

Intelligent IGU Integration: A Decade-Long Energy Efficiency Compact

The argon gas content inside an IGU is the lifeblood of its U-value, yet the industry pain point is rapid gas leakage.

Glasvue’s Solution: We rely on the digital integration of Swiss Bystronic automatic sealing lines and Glaston IGU production lines.

Technical Breakthrough: We employ fully automatic online plate-press gas filling technology, monitored in real-time by sensors to ensure the initial argon fill rate is stable above 90%. Combined with high-quality molecular sieve desiccant systems, Glasvue dares to guarantee that the product’s thermal performance remains within the specified range even after 10 years, ensuring energy savings are more than just a paper promise.

Rigorous Lamination Process: Conquering the “No-Go Zone” of Offline Low-E

In commercial facades pursuing both transparency and safety, laminated Low-E was once a “forbidden zone” for processors, as the high-temperature and high-pressure environment of an autoclave could easily cause the fragile silver layer to blacken or deteriorate.

Glasvue’s Advantage: Through deep research into the physical properties of offline coatings, we have developed a unique temperature control and environmental redundancy system.

Core Competitiveness: Even in the most complex lamination processes, Glasvue ensures the Low-E coating remains unharmed. This allows architects to design high-rise or high-security curtain walls without having to choose between “extreme energy efficiency” and “structural safety.”

Case Study: Modbury Hospital, South Australia

In the modernization project of Modbury Hospital in South Australia, architects faced a daunting engineering challenge: how to ensure healing natural light for medical spaces while effectively resisting the extreme summer radiation of the Australian interior? Glasvue provided the perfect answer through a technically representative full-process solution.

The project selected a complex multi-layered configuration: 8mm Triple Silver Low-E (Tempered + Heat Soaked) + 12A (Black Matte Spacer) + 6mm Clear (Heat Strengthened) / 1.52PVB / 6mm Clear (Heat Strengthened). This was not merely a stacking of materials but a test of deep-processing craftsmanship.

The Art of Extreme Light-Heat Balance: Modbury Hospital’s energy requirements were stringent. Glasvue selected world-class offline Triple Silver raw sheets. By deeply understanding the film structure, we achieved extreme control over the Solar Heat Gain Coefficient (SHGC). This means that under the Australian sun, the glass acts as an intelligent barrier, blocking most invisible thermal energy while maintaining a VLT high enough for a bright, comfortable clinical environment.

Peak Performance in Thick Plate Processing and Optical Flatness: Processing 8mm Triple Silver Low-E in large formats increases the difficulty exponentially. Glasvue utilized Glaston high-end forced convection furnaces to precisely overcome the uneven heating issues inherent in thick glass within a thermal reflection environment. The final delivered product not only completely eliminated roller wave distortion but also presented a pure optical flatness. Coupled with the Bystronic line’s online argon filling and black matte spacer technology, the project improved thermal performance while giving the curtain wall a unified, deep industrial aesthetic from every visual detail.

The Glasvue Commitment

At Glasvue, high-performance architectural glass is not a standardized industrial commodity but a deeply customized technical system. To ensure every piece of Low-E glass reaches its theoretical performance limit within a complex architectural context, we have established a full-lifecycle consulting service system.

Pre-Selection Consultation: The success or failure of architectural energy efficiency is often decided at the drawing board. Glasvue’s technical team provides selection recommendations based on the project’s geographic climate zone, Window-to-Wall Ratio (WWR), and orientation using professional calculation models.

Deep-Processing Full-Flow Monitoring: The deep-processing of every high-performance raw sheet is accompanied by a strict “digital resume.” From the precision calibration of automatic edge deletion to the online monitoring of argon saturation, Glasvue achieves full traceability of production data.

Global Logistics Delivery: Glasvue’s footprint is found on iconic buildings worldwide. We understand the rigorous requirements for packaging safety and delivery timeliness in international projects. Therefore, we do everything in our power to ensure the glass arrives on time and in perfect condition.