In 2025, as global attention to energy-efficient buildings continues to rise, insulated glass units (IGUs) are becoming increasingly widespread and a key component in modern window and façade systems. For procurement professionals involved in construction projects, the volume of IGU purchases is expected to grow steadily, making it essential to understand cost structures as the first step toward informed decision-making.

At the same time, more developers and design teams are seeking insight into the relationship between IGU cost composition and performance during the material selection stage, aiming to strike the right balance between project budgeting and energy efficiency outcomes.

This article will guide you through the key cost drivers behind double-glazed IGUs, enhancing your procurement confidence and helping create greater long-term value for your building projects.

Key Cost Factors of Double Glazed Glass Units

How Do Glass Type and Thickness Shape the Main Price?

The biggest factor in IGU costs is the kind and thickness of glass. Regular float glass is the cheapest but offers little in performance. Low-E (low emissivity) glass, however, has a super-thin metal layer that bounces back heat, greatly improving energy savings.

Laminated glass adds cost but brings extra safety and soundproofing. It’s PVB film softens noise by soaking up sound energy through its stretchy, sticky nature. Thicker PVB layers, like 1.14mm or 1.52mm, work best in noisy spots like near roads or factories.

Bigger glass panes need more materials and special care during production and shipping. This raises costs.

How Do Spacer Materials Affect Cost and Performance?

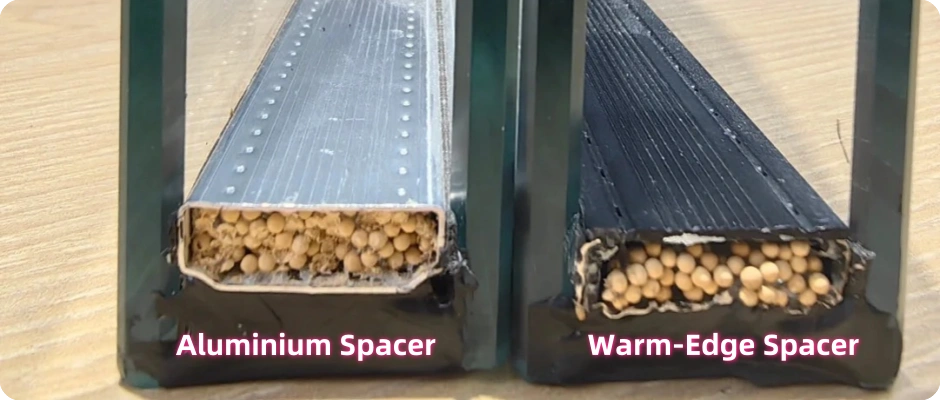

Spacers keep the two glass panes apart in an IGU, holding a steady gap while aiding heat insulation. Old-style aluminum spacers are cheap but let heat pass through easily, weakening insulation.

The greatest advantage of warm-edge spacers over traditional aluminium spacers lies in their significantly lower thermal conductivity, which effectively reduces thermal bridging at the glass edge. This enhances the overall insulation performance of the window, lowers the U-value, and minimises the risk of edge condensation.

Made from composite materials—such as stainless steel combined with plastics or foam polymers—warm-edge spacers not only deliver better energy efficiency but also extend the service life of insulated glass units. As a result, they are widely used in high-performance window systems and energy-efficient buildings.

Is Argon Gas Filling Worth the Extra Cost?

A popular upgrade from air-filled IGUs is filling the gap with argon gas. Argon is heavier than air and slows heat movement across the unit.

For better results, use argon in hollow layers with warm edge spacers to cut heat flow and boost soundproofing. Argon raises costs due to careful filling steps and quality checks. Yet, it can lower U-value (heat transfer) by up to 30%.

For projects targeting eco-standards like Passive House or LEED, argon-filled insulated glass units (IGUs) offer significant energy savings that often justify their modest cost increase. However, their effectiveness comes with challenges, including the risk of undetectable gas leakage and potential long-term performance degradation. To assess their value, key considerations include the quality of sealing technology, the building’s intended lifespan, and local environmental conditions.

Impact of Dual-Seal Systems on IGU Durability and Cost

The distinction between single-seal and dual-seal systems lies in their construction and performance. Single-seal systems rely on a single layer of sealant, typically butyl, which provides basic gas retention but limited resistance to weathering and stress. In contrast, dual-seal systems use a primary butyl seal for airtightness and gas retention, paired with a secondary sealant (e.g., silicone or polysulfide) for enhanced structural integrity and environmental durability. Dual-seal systems offer superior performance, significantly extending IGU lifespan and making them ideal for energy-efficient, long-term building projects.

Why Do Processing Standards Raise the Final Price?

Processing covers cutting, tempering, laminating, polishing edges, or drilling for hardware. These tasks need precise tools and skilled workers.

Tempered glass is safety glass treated to form a tough surface layer. It’s great for tall buildings or impact-prone spots like doors or skylights.

Certifications like CE marking or EN1279 add testing costs. But they’re vital for projects needing proof of performance.

How Does Order Size and Customization Change Unit Price?

Large orders save money through bulk discounts. Less material waste, better shipping plans, and smoother production lower the cost per square meter.

Custom sizes or colored coatings cause production hiccups, raising prices. Far-off delivery spots may also add shipping fees due to careful handling of big glass panels.

2025 Market Trends That May Impact Pricing

How Will Raw Material Costs Change?

Prices for key materials like float glass have swung due to global supply issues since the pandemic. Silver powder for Low-E coatings shifts with market changes. Aluminum prices keep rising as the electric vehicle industries demand more.

These supply pressures directly affect IGU prices, from simple home windows to fancy office façades.

What Hidden Cost Factors Should You Watch?

Making IGUs uses lots of energy, so rising power prices hit manufacturers hard, especially in places moving away from coal without steady green energy yet.

Labor costs are climbing worldwide due to a lack of skilled workers in glass-making jobs. Machines help, but their setup costs trickle into product prices.

Price Doesn’t Equal Value — How to Make Smart Buying Choices

Don’t judge double-glazed units only by cost per square meter. Focus on value points like:

- U-value: Lower means better heat insulation.

- Sound ratings: Key near noisy places like airports or roads.

- Durability: Sealant quality affects how long units last.

- Certification: Proves units meet building codes.

Insulating glass is top-tier for sound and heat insulation. It’s made by bonding two or three glass pieces with strong, airtight glue. Inert gas like argon boosts performance over regular double-layer glass.

For cutting-edge options tailored for modern buildings—from triple-glazed panels for hospitals to soundproof laminated units for offices—check out GLASVUE’s insulated glazing range. Their triple-layer products meet tough global standards while keeping design options open for curtain walls or built-in blind systems.

GLASVUE’s acoustic laminated silent series uses smart interlayer tech tuned for human hearing ranges without adding heavy weight. It’s a great pick when balancing soundproofing with building weight limits.

Recommendations for Buyers Planning a 2025 Purchase

- Look at total costs over the product’s life, not just the starting price.

- Pick Low-E coatings for sun control needs.

- Use argon filling for eco-friendly project goals.

- Choose warm edge spacers in cold areas.

- Ask for bulk price quotes for big orders.

- Check processing abilities before custom orders.

- Ensure suppliers give certification papers upfront.

With these tips and clear knowledge of what drives IGU costs, you’ll be ready to buy double-glazed glass units smartly and confidently for all kinds of projects.

FAQ

Q1: Is Argon-Filled Double Glazing Worth It?

A: Yes, argon greatly boosts heat insulation by slowing heat transfer between panes. For better results, pair it with warm edge spacers to cut heat flow. For buildings chasing eco-standards like LEED or passive house, this upgrade often pays off through lower heating and cooling costs over time.

Q2: What’s the Price Gap Between Low-E and Standard IGU?

A: Low-E coated IGUs usually cost 10–30% more than regular ones due to special coatings with silver powder applied in vacuum processes. But they offer better sun control and lower U-values, making them worth it for energy savings in most climates year-round.

Q3: How to Cut Costs on Double Glazing for Big Projects?

A: Lock in bulk buying deals early in planning. Use standard sizes when possible. Pick nearby suppliers if you can. Choose manufacturers with full processing lines to cut extra handling fees. Use warm edge spacers only where needed for heat savings, not everywhere.